With the demand for spent nuclear fuel transportation and storage applications in China, the fabrication, processing, control of microstructure and properties, and service performance evaluations of the new-style neutron-absorbing B4C/Al composites were investigated. Technical research was performed to fabricate key components used for nuclear fuel transportation equipment.

A powder metallurgy route, including billet fabrication, extrusion, and rolling, was developed for large-size B4C/Al composites. Engineering samples of 450 mm width and 4500 mm length were successfully produced by this route in small batches. Special tools and welding processes were also developed for the friction-stir welding (FSW) of B4C/Al, which could realize high-quality long-distance welding of B4C/Al. Based on the above techniques, tube-shape components with 960 mm diameter,1200 mm height, and 2 mm thickness were successfully fabricated and provided as nuclear fuel transportation and storage containers in the world's first high-temperature gas-cooled reactor NPP (China, independent developers). B4C/Al composites with high temperature resistance and structure-function integration have also been developed, which can potentially be used as dry storage container materials for next-generation nuclear power equipment.

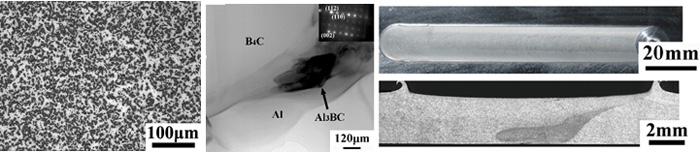

Photographs of B4C/Al Microstructure, Macrostructure of Welding Joint and Engineering Samples Provided in Small Batch

Microstructure and Interface of B4C/6061Al, Macro and Microstructure of FSW Joint

Billets, sheets and the tube-shape components used as neutron absorber containers for nuclear fuel transport