Nickel-based superalloys and the preparation of components thereof, applied in thorium-based molten-salt breeder reactors, are investigated. We focus mainly on the aspects of the effects of trace elements and the morphologies of carbides on the microstructure and properties of alloys, static microstructural and property evolution of long-life alloys, dynamic microstructural evolution of long-life alloys with applied stress, microstructural and property evolution of alloys under service conditions, and the corrosion resistance mechanisms of alloys in fluoride molten salts, in cooperation with the Shanghai Institute of Applied Physics. The engineering application of homemade materials used in the reactor at ~650–700°C is performed, including the melting of large ingots weighing ~10–12 tons; hot-rolling of wide and thick plates measuring 2.2 m× 4.5 m× ~22–40 mm; rolling of large annular components of 3.1 m diameter,1.1 m height, and 40 mm thickness; cold rolling; forging of various billets; and jointing. Meanwhile, nickel-based superalloys used at 800°C in next-generation thorium-based molten-salt breeder reactors are investigated ahead of schedule.

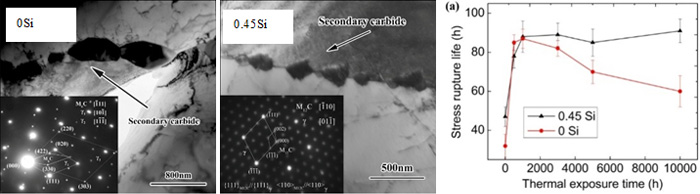

Influence of Trace Element Si on the Microstructure and Property of the Alloy Aged for 1000h at 700℃

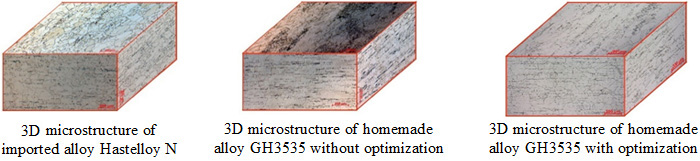

Comparison of Typical Property of Domestic GH3535 Alloy after Optimization of Carbides