An environmental friendly and corrosion protective conversion coating on Mg alloy developed by the corrosion and protection research group of magnesium led by research fellow HAN Enhou and associate researcher SHAN Dayong from Institute of Metal Research(IMR) obtained an evaluation such as “corrosion resistance are quite encouraging for the IMR phosphate pretreatment relative to other pretreatments supplied to the project” in a Canada-China-USA collaborative research & development project due to its excellent overall performance, and the general coordinator of this project from America team proposed that the future development of corrosion protection system for magnesium front end of auto body should be based on IMR conversion coating.

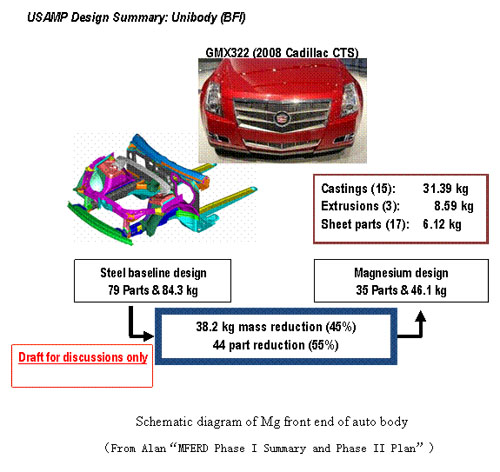

The application of Mg alloy in auto industry has great significance in energy saving and environmental protection. With the support of the governments of China, USA and Canada in 2007, technical personnel from three countries worked together on the project of “Magnesium Front End Research and Development (MFERD)”. According to the design of USA team, the weight of automobile would be decreased by 38.2Kg. It would be a great progress of the integrated application of Mg alloy in automobile.

This international cooperation project would last for 6 years, aimed to research and develop comprehensive application technology suitable for Mg alloy in front end. A great challenge of this project was to establish a corrosion protection system suitable for Mg front end. The general coordinator of this project from USA team sent uniform samples to 11 units (Henkel、Chemetall、AHC、Atotech、MacDermid et.al) which were expert in corrosion protection of Mg alloy. After treated by these units, samples were sent back to the general coordinator and numbered as A to K. USA team entrusted authoritative organization to evaluate the comprehensive properties of coatings related to corrosion protection according to ASTM standard and American Automotive Standard. The experiment results revealed that the corrosion resistance of chromium-free environmental friendly conversion coating developed by IMR (marked as K by USA team) was actually among the best treatments.

Conversion coating treatment is the most popular corrosion protection technical used on Mg alloy. Many treatment methods used in past usually contained hexavalent chromium and had harm to man’s health and environment. IMR research group realized a great progress of low cost and environmental friendly conversion coating treatment technique. This technique has already obtained China national patent and applied for American patent. Moreover, this technique has attained industrialization level.

The IMR conversion coating has the characteristics of excellent corrosion resistance, simple process, low cost, long life of solution, etc. Additionally, the bonding strength of the coating to car body adhesive is high. It has obvious advantages in using on Mg auto components due to its lower cost, and it has wide application prospect in auto industry. In fact, this conversion coating has already been adopted by FAW used on Mg alloy hood shield (Fig.2).

Fig.1 The evaluation result of corrosion resistance suggests superior performance of the “K” treatment.–K-the IMR conversion coating. (from the blind assessment results entrusted by USA team)

Fig.2 Conversion coating on Mg alloy hood shield

Scanning electron microscopy (SEM) of this conversion coating revealed that the coating was compact, surface is smooth. Additionally, relatively few cracks with withered riverbed form reached substrate and it would increase the bonding strength of coating to adhesive (Fig.3a). However, there are deeper cracks in normal phosphate conversion coating (Fig.3b). The characteristics of cracks have great influence on the corrosion resistance of conversion coating. Polarization curve of this type conversion coating presented passivation feature, and it revealed that the coating has superior corrosion protection properties.

Fig.3 Morphologies of conversion coating

a-environmental friendly(K)conversion coating, b- normal phosphate conversion coating

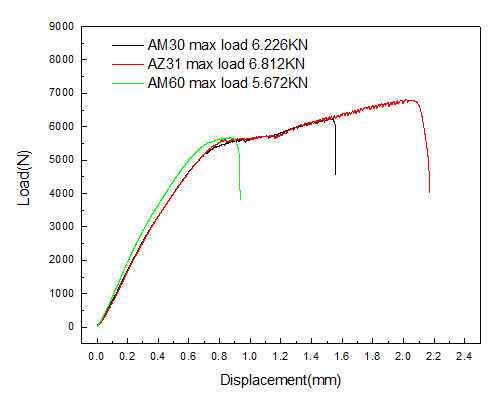

Researchers have carried out the study on the bonding strength of conversion coating to automotive structural adhesive according to the special requirements of automobile industry to conversion coating. According to the requirements of Ford Motor Company about the bonding strength of conversion coating to automotive structural adhesive, bonding strength should higher than 4.5 KN; at present, the maximum value of the bonding strength of this type conversion coating to automotive structural adhesive was 6.8 KN and the minimum value was 5.7KN.It completely achieved the application standard in automobile industry.

Fig.4 Polarization curve of conversion coating with passivation feature

Fig.5 Bonding strength of conversion coating on AM30, AZ31 and AM60 to automotive structral adhesive