Extensive investigations over the past decades indicated that with a substantial reduction of grain sizes into the nanometer regime, the strength of polycrystalline metals is much elevated at an expense of their ductility. Free-standing nano-grained metals are usually very strong but extremely brittle with almost no tensile uniform elongation. The brittleness is believed to be an intrinsic “Achilles’ heel” of nanocrystalline metals as the conventional deformation mechanisms cease to operate: dislocation slip is substantially suppressed by the extremely small grains and grain boundary sliding or diffusional creep is not active enough to accommodate plastic straining. Indeed, limited tensile ductility of nanocrystalline metals is often attributed to the absence of work-hardening of nano-sized grains, so that strain localization and early necking occur immediately after yielding.

In a recent work of Prof. K. Lu’s group at Shenyang National Lab for Materials Science, Institute of Metal Research of Chinese Academy of Sciences, a considerable tensile plasticity is achieved in a gradient nano-grained (GNG) film when a nano-grained Cu film is confined by a coarse-grained Cu substrate. The key to achieve the intrinsic plasticity of the nano-grained structure is suppression of strain localization with a gradient grain size transition. The GNG film exhibits a 10 times higher yield strength and tensile plasticity comparable to the CG substrate and can sustain a tensile true strain exceeding 100% without cracking. A mechanical-driven grain boundary migration process with a significant concomitant grain growth dominates plastic deformation of the GNG structure. The extraordinary intrinsic plasticity of GNG structures offers their potential as advanced coatings of bulk materials. The relevant work was reported in Science (online on 17 Feb. 2011:http://www.sciencemag.org/content/early/2011/02/16/science.1200177).

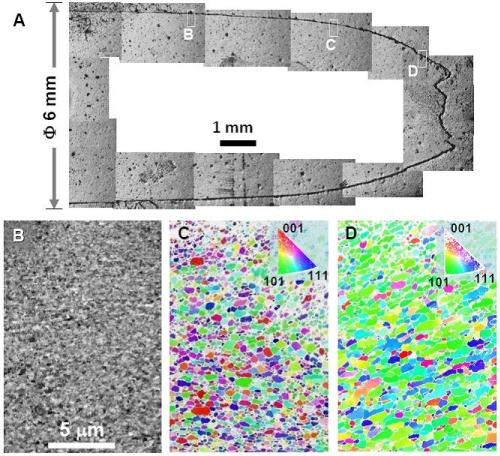

Figure :(A) A cross-section view of one half of the tensile bar GNG/CG sample after failure. (B) A SEM image at position B indicated in (A) with tensile true strains of 24%. (C&D) are EBSD images at position C and D in (A), respectively. B~D showed the grain growth of gradient nano-grained structures with different true strains.