The revolution of aviation technology aims at developing advanced turbine engines with high-propulsion and thrust-to-weight, which is supported by the advancement of environmental barrier coatings (EBCs). EBCs are designed to protect the turbine components made of SiCf/SiC ceramic matrix composites (CMCs) from environmental degradations in the combustion environment, and thus allows for higher core-power of turbine engines. Multicomponent/high-entropy rare-earth disilicates ((nRExi)2Si2O7) are the rising stars for EBCs applications, wherein synergistic optimization on the structural stability, mechanical, thermal and corrosion-resistant properties of the coating materials could be anticipated from the mix-and-matching of key RE ingredients.

However, the design of (nRExi)2Si2O7 materials remains a crucial challenge, due to the versatile combinations of multiple RE elements, as well as the complex polymorphic phase competitions during materials fabrication. Problems pop up, such as how can we precisely and efficiently recognize whether a RE elemental combination should result in successful formation of (nRExi)2Si2O7 with a particular polymorphic phase. Apparently, the trial-and-error materials discovery route is not the best choice.

In a study recently published in Nature Communications (https://doi.org/10.1038/s41467-023-36947-6), researchers from Institute of Metal Research, Chinese Academy of Sciences have uncovered the mechanisms of phase formation capability for multicomponent/high-entropy rare-earth disilicate materials, and proposed a compositional design strategy.

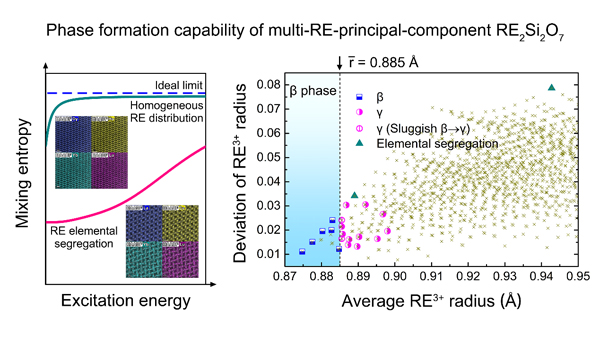

Twenty-one multicomponent (REI0.25REII0.25REIII0.25REIV0.25)Si2O7 (RE = Y, La, Ce, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb, and Lu) have been synthesized. By using X-ray diffraction measurements, Rietveld refinement analysis, and aberration-corrected high-angle annular dark-field scanning transmission electron microscopy, etc., the phase formation and stabilization of these materials is found to be dependent on the average RE3+ radius  as well as the deviations (σr) of different RE3+ combinations.

as well as the deviations (σr) of different RE3+ combinations.

Based on high-throughput density-functional-theory simulations, ensembles containing several hundreds of representative configurations are constructed for model compositions, and the configurational entropy mixing is calculated. Herein, the researchers have proposed a “entropy descriptor”. It well captures whether the configurational randomness brought by multiple RE3+ cations can be sufficiently accommodated in the crystal lattice, and thus could be used to predict the phase formation capability of (nRExi)2Si2O7 materials.

Finally, the strategy to design (nRExi)2Si2O7 materials with controlled phase formation capability and high-temperature stability is proposed, which leads to efficient design and successful synthesis of many new (nRExi)2Si2O7 (n = 2,5,6;equal and non-equal molar fraction of RE) materials. This advancement is expected to push the composition design of multicomponent/high-entropy EBCs materials from the conventional trial-and-error manner up into a quantitative level.

This study was supported by Chinese Academy of Sciences, the Ministry of Science and Technology of China, the National Natural Science Foundation of China, and the Organization Department of Liaoning Provincial Party Committee.

The entropy descriptor, and the r-related criterion for (nRExi)2Si2O7 design. (Image by IMR)