Topic: Stress Corrosion Cracking and Environmental Effects on Fracture of Structural Materials in Nuclear Power Systems

Speaker: Dr. Peter L. Andresen

GE Global Research Center, One Research Circle, USA

Time: 9:00am-11:30am, 2:00pm-4:30pm, (Friday) 15, April, 2011

Venue: Lecture Hall in South Campus, IMR CAS

Welcome to attend!

Abstract:

As fatigue and fracture has become better quantified and managed, environmental effects on cracking have become more prominent. The effects of environment on mechanical properties are complex, and not easily anticipated theoretically or fundamentally. Even after many decades of studies in high temperature water, important new issues are often discovered.

The world of environmental cracking has been artificially divided into initiation and growth, although there is no agreement on the crack development regime uniquely associated with initiation. Most parameters that accelerate crack growth also accelerated crack initiation, suggesting that common mechanistic features exist. However, all kinds of phenomena can be responsible for crack initiation, e.g., inclusions and other metallurgical defects, fatigue, oxidation (pitting, grain boundary corrosion, etc.), mechanical cracking of hardened surface layers, weld defects, etc. Further, most data on crack initiation is burdened by poor experimental design: too few replicates, lack of on-line detection of incipient cracking, stress relaxation, unrealistic stress and chemistry conditions, etc.

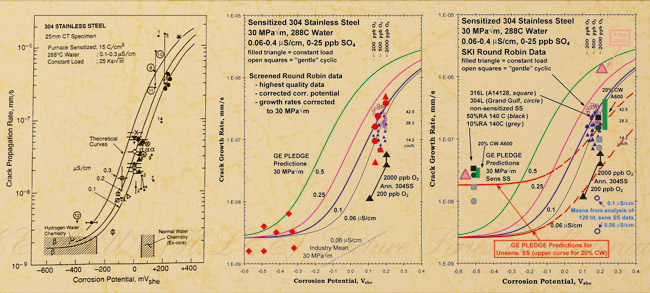

Crack growth studies have proven to be much more quantitative, and inherent resistant to crack advance is key to any design. Stress corrosion crack growth rate data reveal that all grades of stainless steels and nickel alloys are susceptible in high temperature water, whether the dissolved O2 or H2 is high or low, the water is theoretical purity or buffered or contaminated, the temperature lower or higher, etc. Sufficiently high resolution measurements can track SCC response into regimes that were previously hidden “below ground level”, and show that all variables follow a well-behaved continuum and have similar effects in stainless steels and nickel alloys. This suggests that the underlying processes and mechanisms of crack advance are similar in these various alloys and environments. This lecture summarizes the common and the distinctive elements in stainless steel and nickel alloys in boiling and pressurized water reactor environments, including the effects of corrosion potential, water chemistry, cold work, stress intensity factor, temperature, sensitization, Si and grain boundary particles.

Also highlighted is a review of SCC problems in light water reactors and why they occurred, an introduction into some of the underlying science, an emphasis on the need for the highest quality experiments, comments on the general absence of thresholds and immunity in SCC, and an introduction to modeling and life prediction.