It is well known that cyclic deformation behaviors of face-centered cubic (fcc) single crystals have been widely studied since “persistent slip band” (PSBs) was defined as the common presence in fatigued crystals by Thompson et al. in 1956. In 1950’s – 1970’s, a large number of researchers focused on the mechanical and structural characteristics of PSBs, including hardness, distribution, volume fraction, two-phase model and so on. Based on these early works, Mughrabi (1978) established the famous cyclic stress-strain (CSS) curve of single-slip-oriented Cu single crystal, which is the first quantitative determination of the relationship between the macro-scale deformation behaviors and micro-scale dislocation structures. Since 1980’s,Prof. Bretschneider and Prof. Holste have devoted to the cyclic deformation behaviors of Ni single crystals based on the temperature and orientation effects all along. From the early 90s, led by Prof. Zhongguang Wang, State Key Laboratory of Materials Fatigue and Fracture carried out a series of studies around the effect of orientation on the cyclic deformation behaviors of copper single crystals, especially formation mechanism of dislocation arrangements, established a complete set of relationship atlas between the orientation effect and formation of dislocation arrangements. During the same period, various other fcc single crystals, including Al, Cu-αAl, Cu-αZn and so on, were paid much more attentions to the fatigue behaviors. Since 2005, combined with plenty of previous research results, Dr. Peng Li and Prof. Zhefeng Zhang further perfected the research system of fcc single crystals and distinguished the internal and external factors on the formation of dislocation arrangements. Eventually the fundamental principle on evolution mechanism of fatigued dislocation arrangements is summarized as follows:

1. The cyclic deformation behaviors of silver single crystals with different orientations are first systematically revealed. The CSS curves of silver single crystals show a clear plateau region with two saturation shear stresses based on the difference of orientations. The PSB ladders or walls appear in single slip, conjugate double slip and [011] multiple-slip oriented silver single crystals and their plateau stresses are 18~21MPa. A labyrinth structure is formed in critical double-slip oriented silver single crystal and cells are the main structure in coplanar double-slip oriented silver single crystal, whose plateau stresses are 25~26MPa.

2. Combined with the results of nickel, copper and silver single crystals, it can be concluded that the CSS curves of all three crystals show significant plateau behavior and their plateau stresses are 50MPa, 28MPa and 20MPa, respectively. The effects of the orientations on their cyclic deformation behaviors follow the same general principle: the orientation-dependent dislocation configurations can be divided into three regions in the stereographic triangle, including the ladder structure for central region, labyrinth structure for [001], and cell structure for ![]() regions.

regions.

3. Based on two-phase structure consisting of PSBs and veins for single-slip orientation, the formation mechanisms of the dislocation patterns in multiple-slip oriented crystals are proposed as follows: the formation of the complex dislocation patterns depends on the activating slip system. The easy operation of the critical secondary slip system will contribute to the formation of labyrinth structure. The activation of coplanar secondary slip system will be beneficial to the formation of cell structure. If no secondary slip system is activated, the wall structure is more prone to appear. Finally, the intrinsic relationship between various dislocation patterns and fcc crystal structure was established.

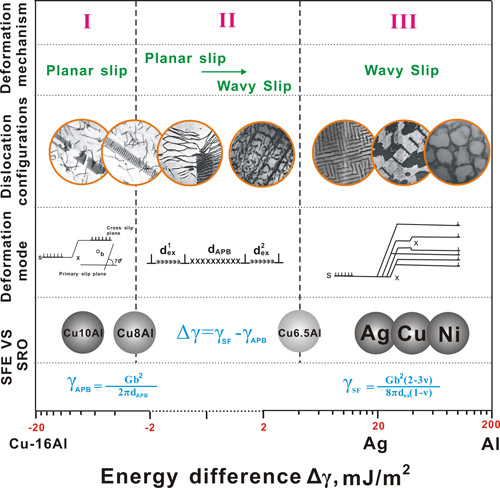

4. In the analysis and comparison of different kinds of fcc single crystals, it is found that the decisive factors on cyclic deformation behaviors are the slip mode, or more generally, the ease of cross slip. According to the effect of slip mode, the materials can be divided into two types: pure metals and alloys. For pure fcc metals, the effect of SFE is decisive. Due to the easy cross slip of screw dislocations, regular dislocation arrangements, e.g. veins, persistent slip bands (PSBs), labyrinth and cell patterns, are always to form. With increase in alloying element, antiphase boundary energy gradually replaces SFE to become a new decisive factor affecting the cyclic deformation behaviors of fcc alloy single crystals. The corresponding dislocation arrangements consist of dipole array and stacking faults (SFs) under the influence of planar slip. The relationship among several factors is well explained, which will help us better understand the nature of the fatigue damage of metallic materials and then improve the performance of the related materials.

The above works were successively published inActa Materialia (2008, 56, 2212; 2009, 57, 4845; 2010, 58, 3281), Philosophical Magazine, Scripta Materialia, etc. The completion of this research is not only beneficial to realizing the nature of fatigue damage and fracture of various fcc crystals, but contributes to better understanding the plastic deformation behaviors of metallic materials, such as the competition relationship between slipping and twinning. Due to the systematic results on the fatigue damage behaviors of fcc metals over the years, Prof. Arzt invited us to write a review paper for publication in Progress in Materials Science, whose title is “Fundamental factors on formation mechanism of dislocation arrangements in cyclically deformed fcc single crystals”. (Link: http://dx.doi.org/10.1016/j.pmatsci.2010.12.001).

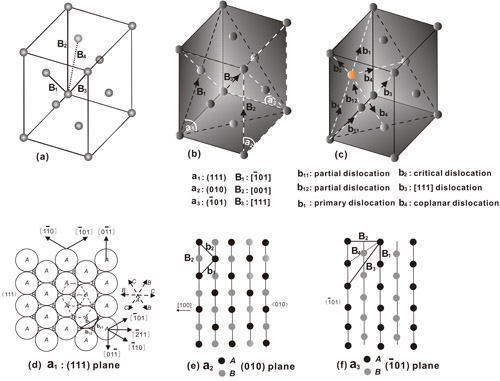

Fig. 1 Dislocation movement and selection of slip systems: (a) potential Burgers vectors; (b) slip and shear systems with three different Burgers vectors; (c) selection of dislocation pattern movement; (d), (e), (f) formation of slip and shear systems.

Fig. 2 New criterion on the formation of regular dislocation arrangements or not in different kinds of fcc metals or alloys by taking into account the effect of slip mode and the energy difference Δγ.