Although the strength of most nano-structured metals (such as nano/ultrafine-grained metals, nanolayered metallic composites) can be enhanced as the metals have nanoscale microstructures, the ductility of the materials usually becomes degraded evidently due to the premature occurrence of shear bands (SBs), leading to the poor synergy between the strength and the ductility of the nanoscale materials. The key scientific problem is why such large plastic deformation induced by the highly localized strain can easily occur within the fatal SBs? What is the fundamental mechanism?

Supported by the National Natural Science Foundation of China and the National Basic Research Program of China, the research team led by Prof. ZHANG Guangping from Shenyang National Laboratory for Materials Science, Institute of Metal Research (IMR), Chinese Academy of Sciences has recently conducted atomic-scale observations of plastic deformation behavior within indentation-induced SBs of Cu/Au nanolayered composites. Based on the theoretical analysis, they uncovered a new physical mechanism on the locally large plastic deformation characterized by continuous thinning of constituent layers in the SBs. The research findings was published recently in Physical Review Letters (110 (2013) 155502, http://link.aps.org/doi/10.1103/PhysRevLett.110.155502).

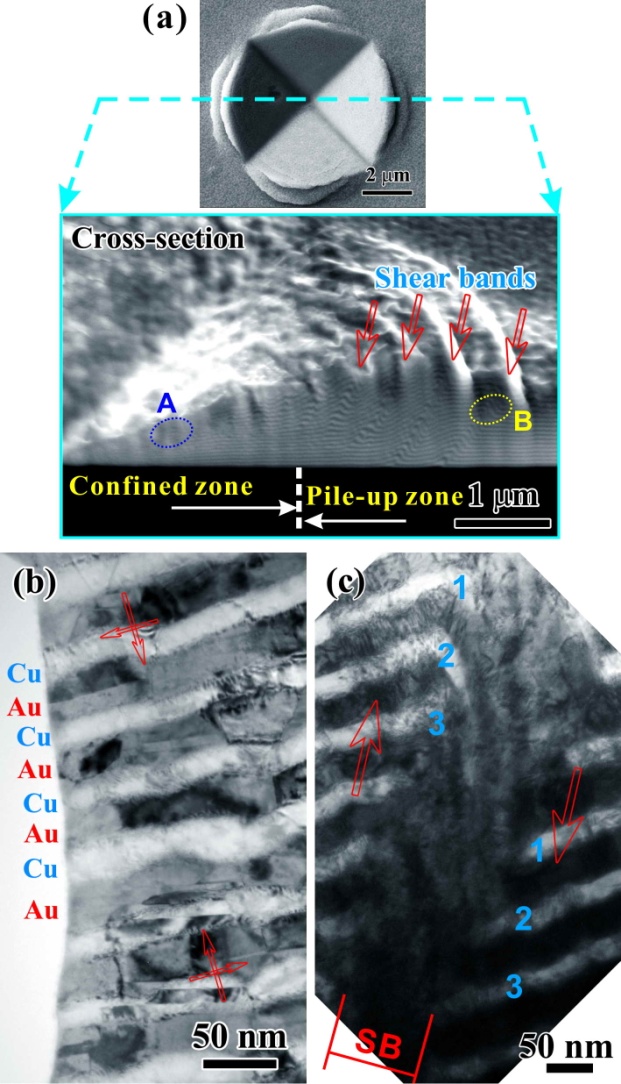

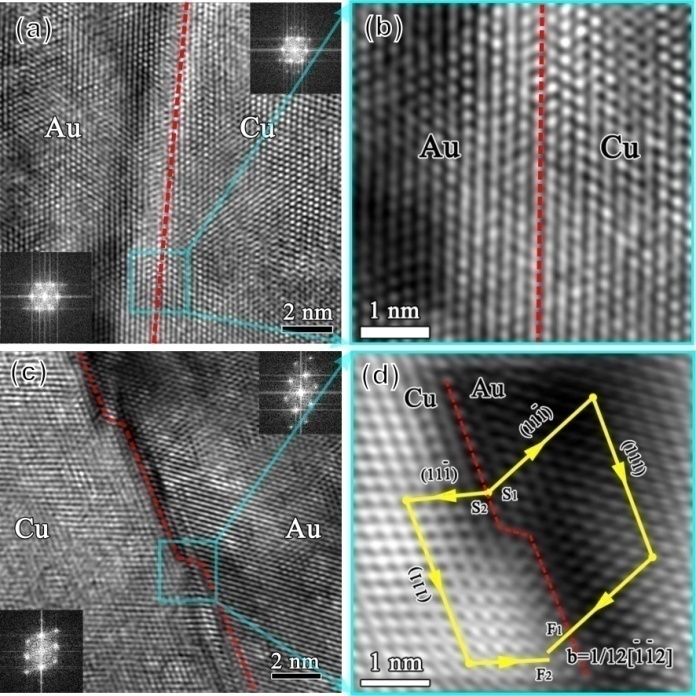

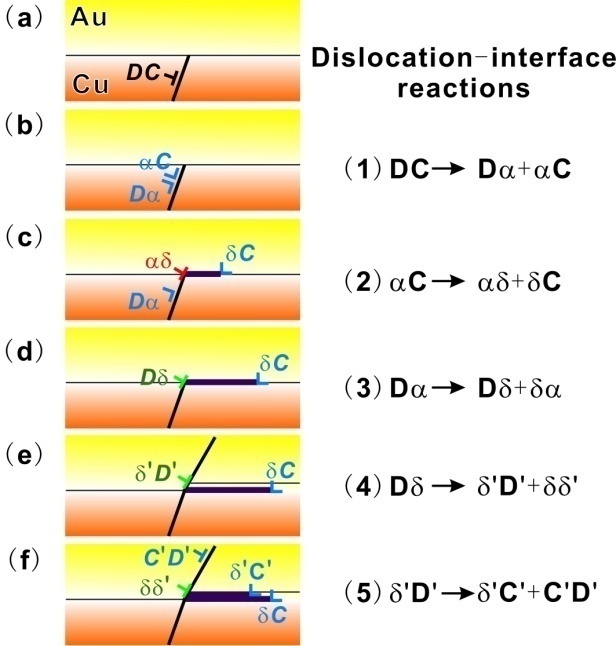

In this investigation, they found that beneath the indent the Cu layers in the confined deformation zone and SBs were subjected to more severe thinning deformation than the Au layers. The experimental observations and theoretical calculations reveal that it was the shear stress along the Cu/Au interface that led to the continuous thinning of the Cu layers. Atomic-scale observations on interface structures and subsequent theoretical analyses show that the interface shear stress could unlock the production of the lattice dislocation-heterogeneous interface reaction, and thus promoted dislocation crossing the interface and led to the continuous thinning of the Cu layers. Based on these results, they proposed a novel mechanism of shear stress-driven refreshing capability of plastic deformation in nanolayered metals.

The results clearly reveal the relationship between the interface-dominated plastic deformation behavior and the shear stress along the interface of the nanolayered metallic composites. The findings can also explain why the grains in some nanocrystalline metals are always deformed and elongated preferentially within SBs oriented along the shear direction. The key role of the shear stress in the stability of nanostructures is stressed.

In addition to being an obstacle to the dislocation transmission, some heterogeneous interfaces in the nanolayered materials, similar to the nanoscale coherent twin boundary, may also have the ability to act as the fresh sinks to continuously absorb the lattice dislocations into the interface, thus accommodate plastic deformation.

The shear stress-driven mechanism provides a valuable guideline to the processing of nano-structured metals by means of severe plastic deformation technique, such as equal channel angular pressing, high pressure torsion and repeated cold drawing, etc.

Fig. 1 Microscopic observations of indentation-induced plastic deformation behavior of Cu/Au nanolayered composites, (a) SEM images of shear banding, TEM images of (b) confined zone and (c) shear band. (Image by IMR)

Fig. 2 High resolution TEM observations of Cu/Au interfaces (a) and (b) before, and (c) and (d) after indentation-induced plastic deformation.(Image by IMR)

Fig. 3 Schematic illustration of physical mechanism of shear stress-driven refreshing capability of plastic deformation in Cu/Au nanolayered composites. (Image by IMR)

For details, please contact: Prof. ZHANG Guangping

E-mail: gpzhang@imr.ac.cn;

Tel: +86-024-23971938