The deformation mechanism of body-centred cubic (bcc) metals has been a subject of long-standing interest to physicists and materials scientists. Bcc metals demonstrate significant variations in mechanical behaviors from face-centred cubic (fcc) metals, due to their lattice crystallography and high lattice friction. While the plasticity of bcc metals is thought to be governed by screw dislocation, other plastic deformation mechanisms were predicted by simulations or experiments. Among these deformation mechanisms, stress-assisted phase transformation is often an efficient outlet to accommodate the imposed straining, such as in transformation-induced plasticity steels and shape memory alloys. However, up to now, no experiment has resolved the dynamic atomistic mechanism of the phase transitions in bcc metals under external forces at room temperature.

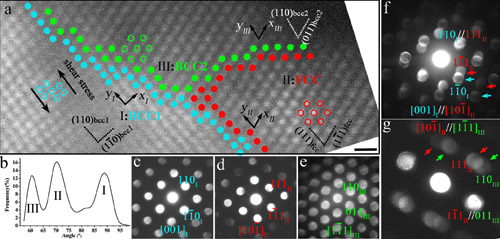

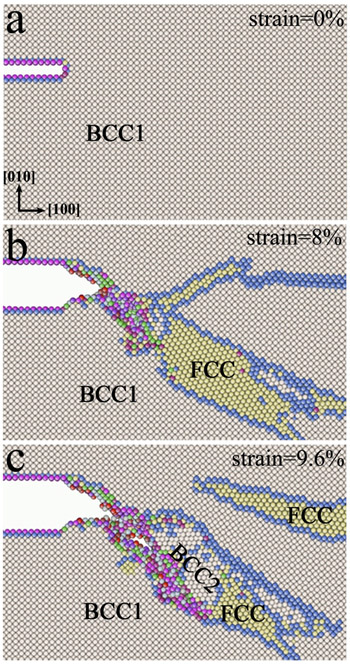

Recently, scientists from Shenyang National Laboratory for Materials Science, Institute of Metal Research, Chinese Academy of Sciences demonstrated a structural transformation accompanied by shear deformation from an original <001>-oriented body-centred cubic structure to a <110>-oriented face-centred cubic lattice, captured at crack tips during the straining of molybdenum inside a transmission electron microscope at room temperature. The face-centred cubic domains then revert into <111>-oriented body-centred cubic domains, equivalent to a lattice rotation of 54.7°, and about 15.4% tensile strain is reached. The face-centred cubic structure appears to be a well-defined metastable state, as evidenced by scanning transmission electron microscopy and nanodiffraction, the orientation relationships between the face-centred cubic and body-centred cubic structures and molecular dynamics simulations. The findings reveal a deformation mechanism for elemental metals under high-stress deformation conditions. The two-step phase transition, bcc1 via fcc to bcc2, constitutes a new route for lattice rotation during deformation. Considering that nanometer-sized materials/devices are likely to experience some extremely complicated stress conditions in their applications, thus, this mechanism may be important for nanomaterials deformed under high-stress conditions.

This work is published recently in a Nature Communications paper (5:3433 (2014), doi:10.1038/ncomms4433). The work is supported by the Special Funds for the Major State Basic Research Projects of China and the National Natural Science Foundation of China.

Figure 1 Three structural variations in Mo. Atomic-resolution high-angle annular dark-field scanning transmission electron microscopy image showing regions I, II and III with different crystal structures or orientations. Atoms are represented using different colours: blue for the original <001>-bcc1 region, red for the <110>-fcc region and green for the <111>-bcc2 region. (Image by IMR)

Figure 2 Snapshots showing the structural transition during the molecular dynamics simulation. (Image by IMR)

Figure 3 Time-resolved HRTEM images showing structural changes during unloading. The lattice shear distortion determined from HRTEM images analysed by the lattice distortion analysis (LADIA) software. (Image by IMR)

CONTACT:

Dr. DU Kui

Institute of Metal Research, Chinese Academy of Sciences

Email: kuidu@imr.ac.cn