China has the largest production capability of polyvinyl chloride polymer (PVC) in the world which reaches 2000 ton per year and is up to 41% of the global production. Over 70% PVC products in China are using the mercury based catalysts which cause severe environmental effects. There are continuous efforts to search the alternative catalyst material to replace the mercury which will have enormous environmental and economical impacts.

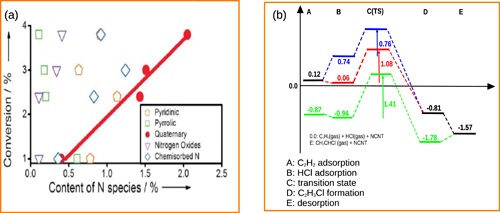

Recently, a collaborated research carried out by Prof. LI Bo and Prof. SU Dangsheng from the Institute of Metal Research and Prof. WEI Fei from Tsinghua University found that the nitrogen doped carbon nanotube catalysts show the remarkable catalytic performance in the reaction of hydrohalogenation of acetylene. This work is selected as the back-cover article in ChemSusChem (2014, 7, 723-728) and reported by the Materials View China(http://www.materialsviewschina.com/2014/04/lv-yi-xi-lv-se-he-cheng-ti-dai-gong-di-chan-dan-tan-cui-hua/). It reveals that the nitrogen doping is the key for enhancing the catalytic performance. After doping, the carbon nanotube catalysts exhibit the comparable performance with the conventional metal catalyst and its TOF reaches 2.3x10-3 s-1 which has great potential for the industrial applications. More importantly, the stability of the carbon catalyst under the working condition is much better than the most metal catalysts. The concentration of quaternary nitrogen in the catalyst is in a good linear relationship with the conversion which indicates that it is the active center. Furthermore, the first principles calculations reveal the three different reaction pathways and the adsorption of the acetylene is the most important step during the reaction which determines the following pathway to proceed. The nitrogen doping enhances the acetylene adsorption which leads to a better catalytic performance. Through the electronic structure analysis, the interacting mechanism between the adsorbed acetylene and the carbon catalyst is different from the counterpart on the metal catalyst. The difference is resulted from the modifications on the acid-base property brought by the nitrogen doping. The current work once again justifies the importance of the metal-free nanostructured carbon catalysts in the process to replace the conventional metal catalyst and opens the new opportunity to produce PVC in an environmental and economical way.

Other heteroatoms such as oxygen, boron and phosphor on the nanostructured carbon catalyst also play an important role for the optimization of the catalytic performance besides the nitrogen. Recently, the researchers from the Catalyst and Materials Division in Shenyang National Laboratory for Materials Science (SYNL) carried out a series studies on the redox and acid-base properties of these heteroatoms. Some works have been published in several international journals including J. Phys. Chem. C, 2013, 117, 17485-17492; Chem. Asian J., 2013, 8, 2605-2608; J. Mater. Chem. A, 2014, 2, 5287-5294; Chem. Eur. J., 2014, doi: 10.1002/chem.201400347.

The works are partly supported by T.S. Ke Research Fellowship, NSFC, and Sheyang Branch of Supercomputing Center of CAS.

Figure 1. (a) The relationship between various nitrogen species and the conversion.

(b) The reaction pathways obtained from the calculations.

Contact:

Prof. LI Bo

Catalysis and Materials Division, Shenyang National Laboratory for Materials Science, Institute of Metal Research, Chinese Academy of Sciences

72 Wenhua Road, Shenyang, 110016, P. R. China

E-mail: boli@imr.ac.cn

Tel: 0086-24-83970027