Coking is widespread phenomena and generally happened during the catalytic reaction process. Especially in the ethylbenzene direct dehydrogenation reaction, the ethylbenzene prefers to decompose and form coking on the surface of metal oxide catalysts, resulting in the deactivation of the metal oxide catalyst. Associated Prof. LIU Hongyang and Prof. SU Dangsheng from Shenyang National Laboratory for Materials Science, Institute of Metal Research, Chinese Academy of Sciences designed a novel Pd/C catalyst, by means of the coking process in the ethylbenzene direct dehydrogenation reaction. In addition to the novel structure, the sinter-resistant ability of as-prepared Pd/C nanocomposite was much better than that of commercial carbon nanotube supported Pd (Pd/CNT) catalyst. The as-prepared Pd/C nanocomposite has a high recyclability in a liquid-phase Suzuki coupling reaction. This strategy may be extended as a general approach to prepare metal nanoparticles. This work was published as a communication on the journal of Angewandte Chemie International Edition, http://onlinelibrary.wiley.com/doi/10.1002/anie.201406490/abstract.

Palladium (Pd) has attracted considerable attention due to their potential applications in catalysis, gas sensor, energy conversion and fuel cells. However, the high surface energy of metal NPs makes them easily agglomerated or shape-changed during catalytic reactions, resulting in the dramatic decrease of their activity and selectivity. To avoid aggregation, considerable efforts have been made by depositing metal NPs on various solid supports, such as silica, zeolite, alumina, metal oxide, carbon, polymers and other composites. Among a wide variety of these supports, carbon supported metal NPs are of particular interest for their various promising applications.

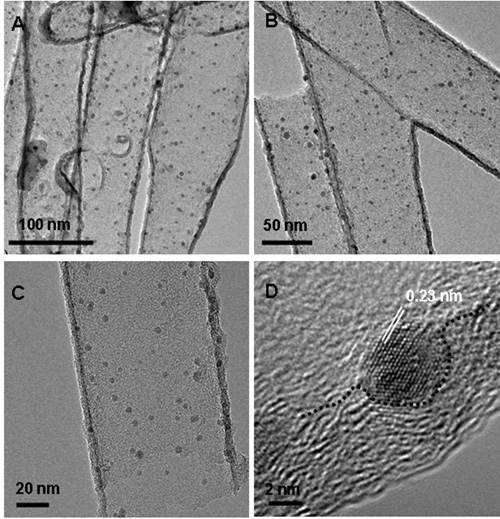

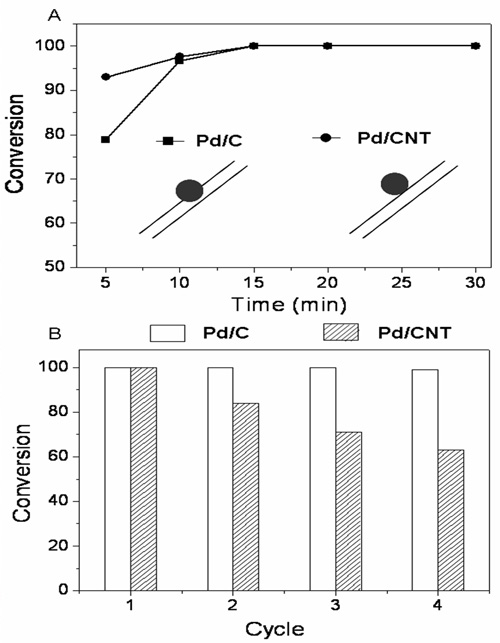

Recently, the team of associated Prof. LIU Hongyang and Prof. SU Dangsheng has developed a novel Pd/C nanocomposite, employing the coking process in the ethylbenzene direct dehydrogenation reaction. TEM images displayed that the Pd nanoparticles was partially embedded in the carbon wall, which can distinguishingly enhance the interaction between the Pd nanoparticles and the carbon support. The high temperature treating experiments show that the average size of the Pd NPs in the as-prepared Pd/C nanocomposite is well maintained after treating the catalyst in He at 500oC for 4h. However, as to the CNT-supported Pd catalyst, after high-temperature treatment, the average size of the Pd NPs dramatically increases from 2-4 nm to 5-10 nm. Meanwhile, the as-prepared Pd/C nanocomposite has a high recycle ability in a liquid-phase Suzuki coupling reaction, which shows its potential application in the industrial catalysis field.

This work is financially supported by National Natural Science Foundation of China (No. 21203214, 21133010), the National Basic Research Program (973 Program, No. 2011CBA00504), the Strategic Priority Research Program of the Chinese Academy of Sciences, Grant No. XDA09030103, and the Sinopec China No. 21203214.

Figure 1.The scheme of fabrication of Pd/C nanocomposite and TEM images of Pd/C with different magnifications.(Image by IMR)

Figure 2.(A) and (B) TEM images of the as-prepared Pd/C nanocomposite after treating in He for 4 h at 500 °C, (C) and (D) TEM images of the fresh Pd/CNT catalyst, (E) and (F) TEM images of the Pd/CNT catalyst after treating in He for 4 h at 500 °C. (Image by IMR)

Figure 3. (A) Conversion of iodobenzene in Suzuki coupling reaction for the as-prepared Pd/C nanocomposite and Pd/CNT catalyst. (B) Conversion on recycling of the Pd/C nanocomposite and Pd/CNT. Inset is the schematic diagram of the location of Pd NPs on the different carbon supports. (Image by IMR)