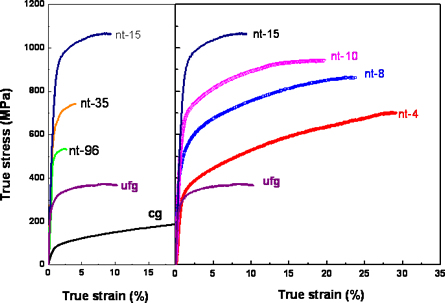

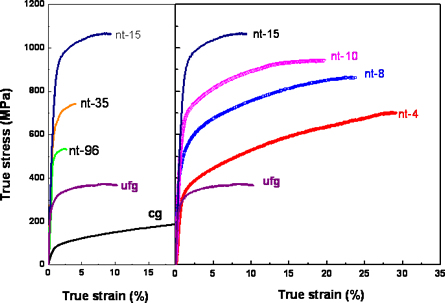

The strength of polycrystalline materials is well-known to increase with decreasing grain size. Below a certain critical size (in the nanometre scale), atomistic simulations suggested that the dominating deformation mechanism is transferred from lattice dislocation activities to grain boundary (GB) related mechanisms and a softening phenomenon is expected. Nevertheless, such a critical grain size of maximum strength has never been identified experimentally so far. Coherent twin boundaries (TBs), a special kind of low-energy boundary, are known to be as effective as conventional GBs in strengthening materials and significant strengthening has been obtained in Cu when high densities of nano-scale (<100nm in thickness, l) twin lamellae are introduced into submicrometre-sized grains. Recently, we report a discovery of a twin thickness of 15 nm giving the highest strength in the nano-twinned Cu (nt-Cu), which is followed by a rapid softening at smaller twin thicknesses and a significant enhancement in both the strain-hardening and tensile ductility. The twin thickness of highest strength relates to a transition in the yielding initiated from a mechanism by the slip transfer across TBs to a mechanism by the motion of pre-existing mobile dislocations. This finding reveals the scale-dependent nature of plastic deformation of materials in the nanometre scale, which is of significant and direct implication in developing advanced nanostructured materials with novel properties (See L. Lu, X.H. Chen, X.X. Huang and K. Lu, Science, 323(2009)607).