Aluminum-based metallic glasses represent an important family of amorphous metals, because of their desirable properties such as high specific strength, good ductility and good corrosion resistance. Of particular interest is their exceptional specific strength, which is twice or above that of conventional crystalline aluminum alloys. However, Al-based alloys have relatively low glass forming ability (GFA) as compared with other bulk metallic glass (BMG) forming systems. As a result, the search for Al-rich BMGs has met with major difficulties since the early 1990s, despite the large number of studies conducted.

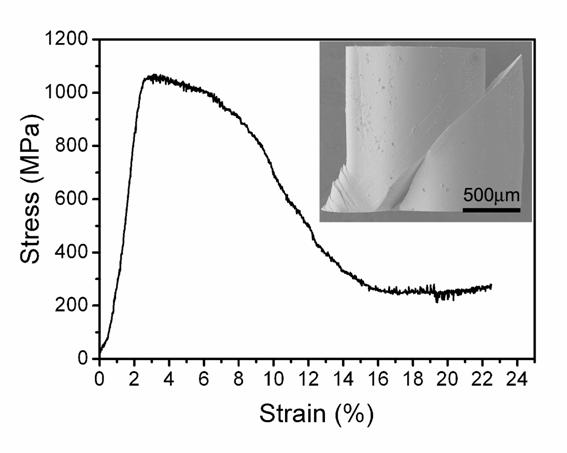

Only recently, Prof. Dr. Jianqiang Wang( Shenyang National Lab for Materials Science, Institute of Metal Research, Chinese Academy of Sciences) and Prof. Evan Ma (Department of Materials Science and Engineering, Johns Hopkins University, USA) cooperated towards that end. Fully glassy 1 mm Al-rich BMG rods have been obtained in the Al-Ni-Y-Co-La systems by copper mold casting, based on an alloy composition design strategy from the preferable internal glass structure. Here we report the first success of obtaining Al-rich (86 at.% Al) bulk metallic glasses (BMGs). The Al BMGs discovered exhibit ultrahigh specific strength of 3.34×105 Nm kg-1 (this BMG has a mass density of 3.14 g cm-3),which is higher than that of existing engineering alloys, as well as obvious plasticity. This discovery is expected to stimulate another surge of interest in the development and applications of light-weight BMGs with unique combinations of desirable properties.

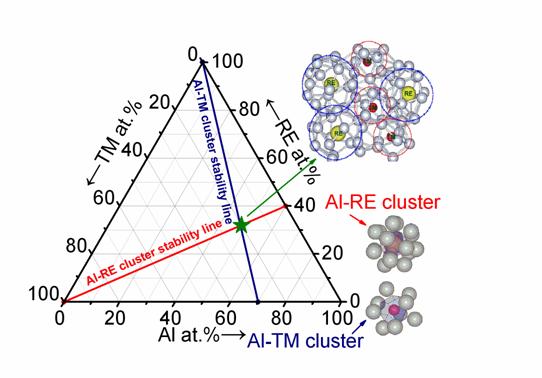

Figure 1.An illustration of our composition design scheme using the cluster stability lines in the Al–TM–RE ternary alloy phase diagram. The two lines corresponding to the ternary addition to the two respective binary clusters are shown for the whole system. The green star symbol at the intersection of the two lines is the favorable composition predicted.

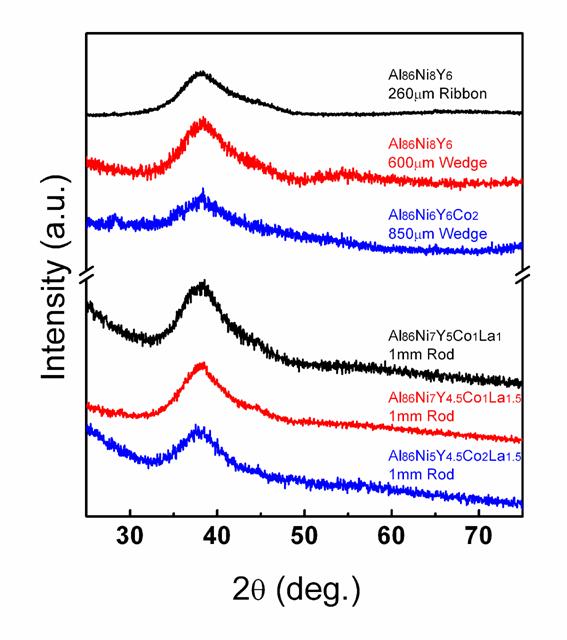

Figure 2.XRD patterns taken from a series of the Al-based glassy alloys from the ternary to the quinary system, for as-spun ribbons, wedge-casting samples and as-cast rods 1 mm in diameter.