Materials with nanometer-scale twins have attracted intensive research interest, attributed to their potential for achieving simultaneous high strength and good ductility. The mechanical properties are associated with interactions between lattice dislocations and the coherent twin boundaries (TBs), as TBs serve as strong barriers for the motion of dislocations. Accordingly, the strength of nanotwinned metals supposedly increases with decreasing twin lamella spacing. Nevertheless, when twin lamella spacing decreases below a critical thickness, approximate 15 nm for nanotwinned copper, a softening behavior instead of strengthening prevails for the yield strength. Molecular dynamics (MD) simulations suggested that the softening corresponds to the dominant activity of Soft mode dislocations below a critical twin lamella spacing, where the dislocations nucleate from the twin boundary/grain boundary (TB/GB) intersections. Hence, quantitative electron microscopy investigations are desirable to resolve the actual deformation mechanisms in nanotwinned metals and their relationship with the mechanical properties.

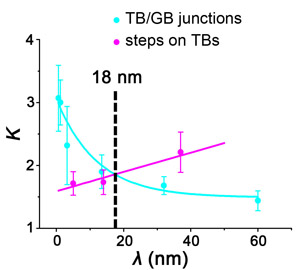

Recently, scientists in Shenyang National Laboratory for Materials Science, Institute of Metal Research, Chinese Academy of Sciences, have investigated an equiaxial-grained nanotwinned Cu with a combination of in situ transmission electron microscopy and quantitative strain analysis. The local stress concentrations for dislocation nucleation are determined varying significantly with twin lamella spacing, thus resulting in a critical twin lamella spacing (~18 nm) for the transition between the nucleation of Soft and Hard mode dislocations. These results demonstrate a direct relationship can be resolved between the microscopic dislocation activities and macroscopic mechanical properties of nanotwinned metals.

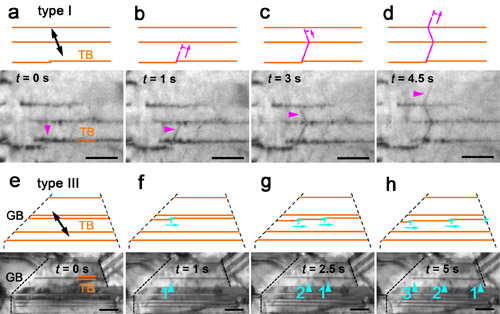

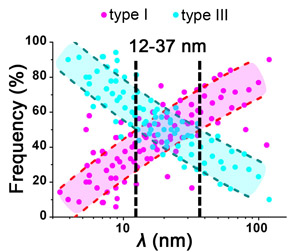

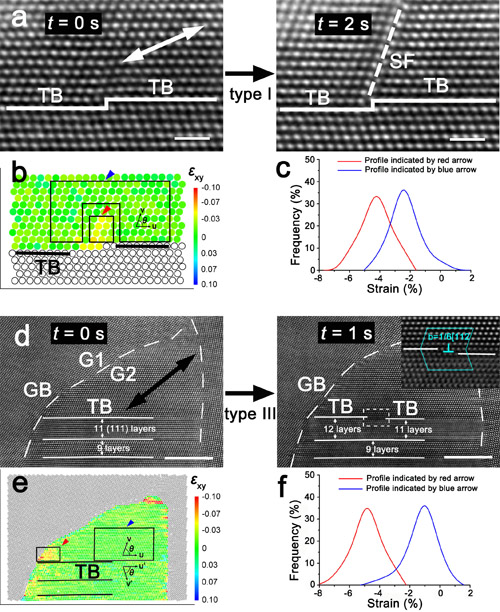

Two main dislocation activities are observed in the incipient deformation of nanotwinned Cu by in situ TEM: type I dislocations are emitted from steps on TBs and glided on {111} planes inclined to the TBs, while type III dislocations are emitted from twin boundary/grain boundary (TB/GB) junctions and slip on the TBs. The activity of type I dislocation decreases with decreasing twin lamella spacing. This is in contrast to type III dislocations, which increase significantly with decreasing twin lamella spacing. This competition is governed by the stress concentration at the steps on TBs and TB/GB junctions. In addition, a strong dependence of twin lamella spacing on the local stress concentration is detected; thus, a critical twin lamella spacing is determined as approximately 18 nm for the transition from strengthening to softening in nanotwinned Cu. The result agrees quantitatively with the experimentally measured critical spacing (15 nm). These data provide insights into connecting the local dislocation behaviors and predicted mechanical properties of bulk materials with geometrically designed nanostructures.

The research is supported by National Natural Science Foundation of China and National Basic Research Program of China. Corresponding paper is published in Nature Communications 6:7648 (2015), DOI: 10.1038/ncomms8648。

Contact:

Prof. DU Kui

Email:kuidu@imr.ac.cn

Institute of Metal Research, Chinese Academy of Sciences

72 Wenhua Road, Shenyang, Liaoning, 110016, China

Full text (http://www.nature.com/ncomms/2015/150716/ncomms8648/full/ncomms8648.html)

Fig. 1 (a-d) Dynamic process of a type I dislocation nucleated from a step on a coherent TB and then glided on a {111} plane inclined to the TB. (e-h) Dynamic process of a sequence of type III dislocations emitted from a TB/GB junction and then glided along the TB. (Image by IMR)

Fig. 2 Proportions of type I and III dislocations are indicated by magenta and blue symbols, respectively. (Image by IMR)

Fig. 3 (a) Dynamic process of type I dislocations emitted from a step on the TB. (b) The lattice shear strain determined before the emission of type I dislocation. (c) Quantitative shear strain analysis of the black-box regions indicated by red and blue arrows in (b). (d) Dynamic process of type III dislocations emitted from TB/GB junction. (e) The lattice shear strain determined before the emission of type III dislocation. (f) Quantitative shear strain analysis of the black-box regions indicated by red and blue arrows in (e). (Image by IMR)

Fig. 4 The stress concentration factors K measured at steps on TBs and TB/GB junctions for nanotwinned Cu with different twin boundary spacings λ. (Image by IMR)