Porous metals have attracted much attention for application such as lightweight structure, energy absorber, heat exchanger, biomaterial, and catalyses etc, and the fabrication methods of porous metals are various. Dealloying is demonstrated to be a reliable process for producing a variety of nanoporous metals in bulk form, as thin films, or even as nanowires. At present, dealloying process were usually based on chemical or electrochemical principle by selective dissolution of one element out of a bimetallic alloy.

Recently, the research team of Associated Prof. REN Yibin from Specialized Materials and Devices Division, Institute of Metal Research, Chinese Academy of Sciences has developed a novel physical vacuum dealloying(PVD)approach to fabricate micron porous metal by physical sublimation in vacuum environment, and the micron pore size make up the range of size for dealloying technology.

Physical vacuum dealloying is a common process by subliming one or more metal components in alloy to form the porous metal, the theoretical foundations of physical vacuum dealloying are the sublimation and Kirkendall effect. It is acknowledged that the Kirkendall effect may lead to so-called “Kirkendall voids”, and these Kirkendall voids were generally considered as a nuisance because they deteriorate the properties of the alloy. In contrast, the Kirkendall effect has been positively used as a new fabrication route to form porous metal in this study.

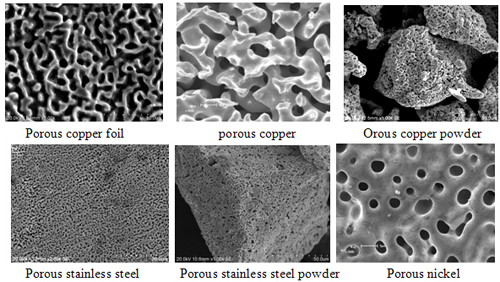

Porous copper is an interesting electrode material for the electrolysis process, micron porous copper was prepared successfully by physical vacuum dealloying (PVD) of CuZn alloy, which showed a three-dimensional continuous porous structure with pores size of 2-5μm. This work was published on the Materials Letters (doi:10.1016/j.matlet.2015.11.102). Porous copper powder was also prepared successfully by vacuum dealloying using Commercial brass powder. This work was published as a rapid communication on the Vacuum (doi:10.1016/j.vacuum.2015.09.031).

Porous nickel and porous stainless steel also been prepared by physical vacuum dealloying method, these dealloying processes have been applied for 5 Chinese Patent and 1 International Patent.

Contact:

Associated Prof. REN Yibin

Email:ybren@imr.ac.cn

Institute of Metal Research, Chinese Academy of Sciences, 72 Wenhua Road, Shenyang, Liaoning, 110016, China