The use of fatigue data in material design has increased over the years, considering most of engineering structures and components are served under cyclic loading condition. One of the main problems that fatigue analysis aims to solve is to find ways to improve material's fatigue property, which is directly related to money saving and promoting the development of the industry.

To date, significant developments have been achieved to optimize metals’ fatigue resistance. Examples include optimizing alloy composition, reducing grain size, producing pre-strain in ductile material by cold work, as well as surface pretreatment. While these methods are substantially effective for the stress controlled fatigue in high-cycle regime, it remains an open question how to enhance the fatigue life in low-cycle region.

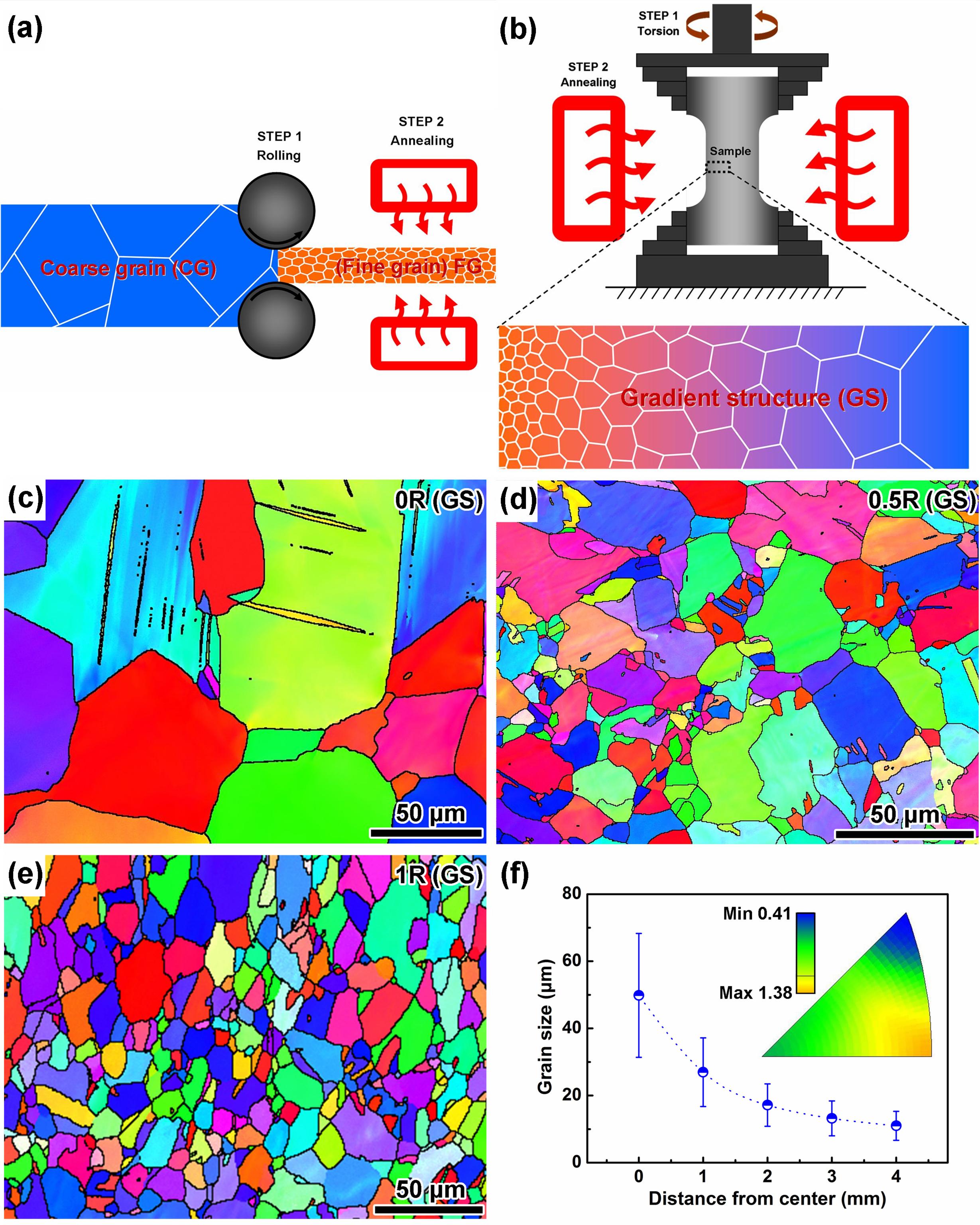

Recently, two strategies and technologies to improve the low-cycle fatigue (LCF) performance of Fe-Mn-C twinning induced plasticity (TWIP) steel were proposed by Prof. ZHANG Zhefeng’s group in Institute of Metal Research, Chinese Academy of Sciences (IMR, CAS). One is grain refining without introducing residual stress by traditional cold rolling and following recrystallization annealing (FG sample); the other is to introduce a linear gradient in grain size into TWIP steel by the original processing technology (GS sample).

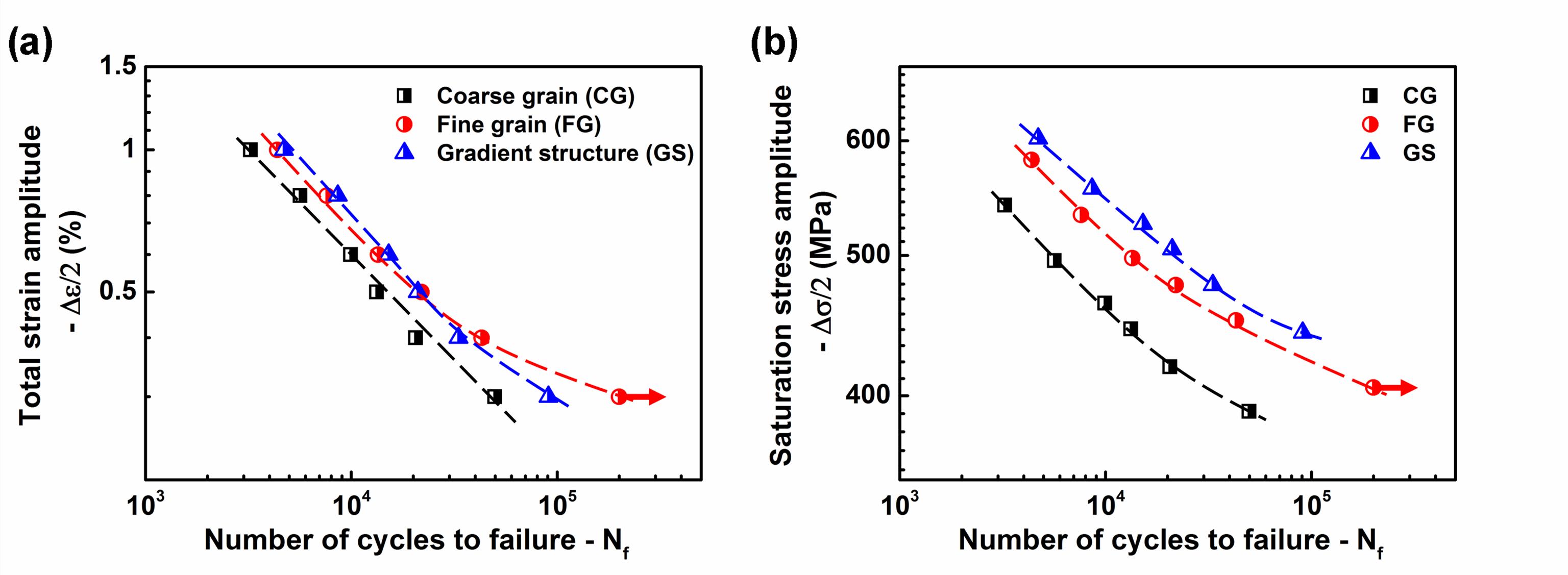

It is found that GS samples exhibit a higher cyclic hardening ability and cyclic saturation stress than that of as-received coarse grain (CG) samples and FG samples, which invalids the rule of mixture. The excellent fatigue properties of GS are believed to originate from the large generation of geometrically necessary dislocations (GNDs) and the formation of hard core and soft shell structure during cyclic loading. The significant influences of grain size and distribution on fatigue damage mechanisms may provide new and important implications for the optimized microstructural design of the high fatigue performance material.

This work has been recently published online in Acta Materialia.

Figure 1 (a,b) Illustrations of sample preparation. (c-f) Evolution of grain size as a function of the radial position in the GS sample.

Figure 2 LCF properties of CG, FG and GS. (a) Relationship between total strain amplitude and fatigue life; (b) dependence of fatigue life on saturation stress amplitude.