Metallic glasses (non-crystalline alloys) are of interest for their exceptional (sometimes record-breaking) property combinations, for example, high yield stress combined with high toughness. As a non-equilibrium metal with various energy states depending on preparation conditions, metallic glasses tend to relax to the lower-energy states at low or high temperatures, accompanied by the deterioration of plastic deformation ability.

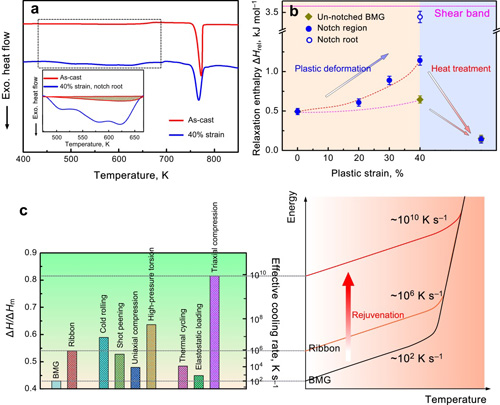

Therefore, it is of great importance from scientific and engineering aspects to take the glasses to the higher-energy states, i.e. rejuvenation. One common way to rejuvenate metallic glasses is plastic deformation, but the level of rejuvenation is rather limited, and the resultant energy state is even lower than that of ribbons.

Recently, Dr. PAN Jie et al. from Prof. LI Yi's team at the Institute of Metal Research, Chinese Academy of Sciences used constrained compression, where shear banding is suppressed and significant homogeneous flow is achieved throughout the whole specimen, to rejuvenate bulk metallic glasses to the extreme high energy state that would be typical of a glass formed on cooling at 1010 K s–1.

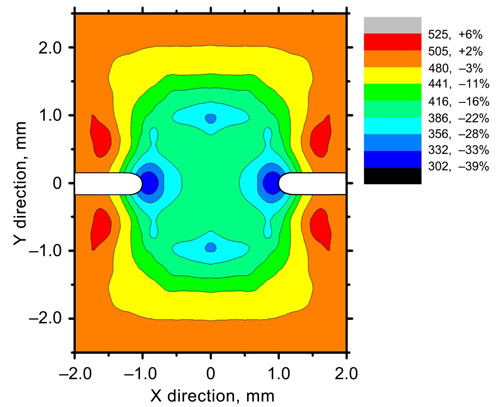

It is 7 to 8 orders of magnitude higher than the cooling rate at which the sample actually formed, and orders of magnitude higher than that of ribbons. In the extremely rejuvenated metallic glasses, the maximum measured effects are that the hardness of the glass decreases by 36%, and its excess enthalpy increases to 41% of the enthalpy of melting, also far higher than those in deformed glasses through shear banding.

In addition, extreme rejuvenation occurred in a large region with mm-scale, which also provides an ideal material to study the subsequent structural change and mechanical properties.

This work entitled "Extreme rejuvenation and softening in a bulk metallic glass" has been published online in Nature Communications.

Figure 1 Map of hardness measured on the cross-section of a notched cylindrical (4 mm diam.) sample of metallic glass compressed along the vertical cylinder axis. The yellow region and those within are rejuvenated; the blue colour indicates the regions of extreme softening and rejuvenation. (Image by IMR)

Figure 2 Extreme rejuvenation by compression of notched glass specimens. (a) Differential scanning calorimetry traces (heating rate 20 K min–1) of Zr64.13Cu15.75Ni10.12Al10 glass: an as-cast specimen and a notched specimen compressed to 40% nominal strain. (b) Relaxation enthalpy △Hrel of specimens of this glass compressed to different strains and annealed. (c) Relative enthalpies of metallic glasses (normalized by the heat of melting △Hm and relative to the annealed crystal) in different as-cast conditions, and subjected to plastic deformation, or to other processes such as elastostatic loading and thermal cycling. Higher relative enthalpy corresponds to glassy states expected to be achieved at higher cooling rates. (Image by IMR)