Nature always inspires material scientists to seek ways to enhance the mechanical properties of engineering structural materials from the structure-property relations in natural materials.

For example, bamboo stems possess a gradient structure that comprises a decreasing density of vascular bundles from their exterior inwards the center, leading to enhanced flexibility yet overall strength and stiffness. Using the inspiration of such natural materials, there have now been several attempts to replicate these gradient structures to create structural metallic materials with similarly favorable combinations of properties.

Although excellent combinations of strength and ductility can be achieved with gradient structures, it’s a challenge to guarantee that the fracture resistance will be similarly superior, as it is the local microstructure that affects the fracture toughness of the materials

A systematic study has been recently carried out by Prof. LI Yi’s team from Institute of Metal Research, Chinese Academy of Sciences (IMR, CAS) to evaluate the fracture properties and crack propagation process in gradient structured (GS) nickel, involving grain size gradients from ~30 nm to 4 μm.

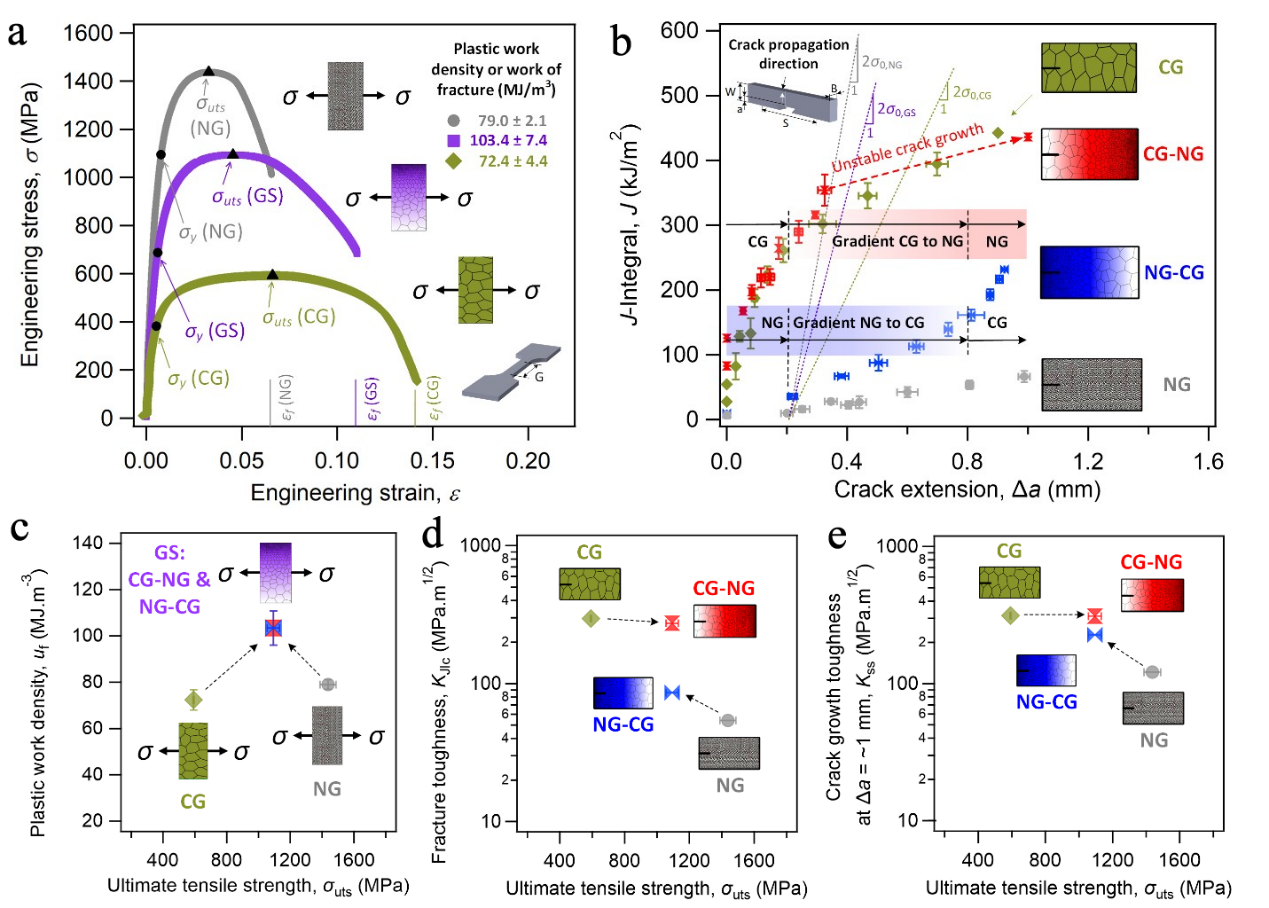

The team found that an optimized combination of high strength and high toughness can be achieved in the gradient structured material, compared to the ultrahigh-strength nano-grained (NG) and low-strength coarse-grained (CG) uniformed grain-sized structures.

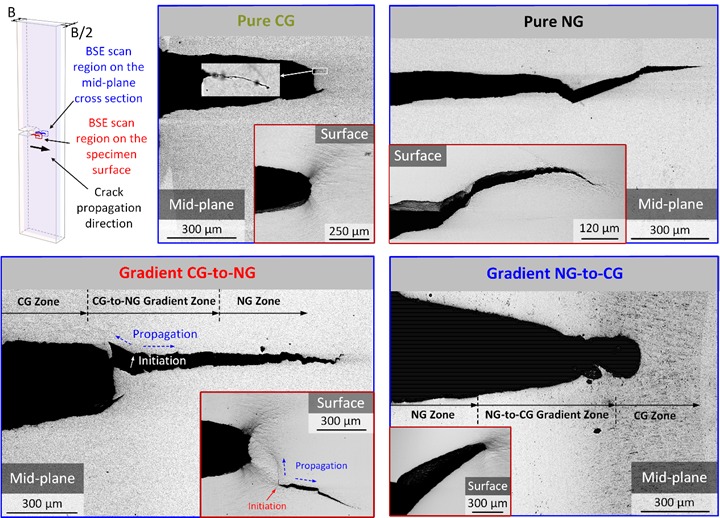

Scientists also found that CG→NG gradient structure, where a pre-existing crack initiates from CG zone and propagates into NG zone, displays the best combination of strength and toughness properties; with largest degree of R-curve toughening behavior, similar to the CG material. Once crack extension approaches the end of gradient structure, however, unstable brittle fracture can occur as the crack encounters the nano-sized grains. Therefore, the CG→NG gradient structure represents a characteristic transition from ductile fracture to brittle fracture.

On the other side, the NG→CG gradient structure, where a pre-existing crack initiates from NG zone and propagates into CG zone, exhibits a degree of R-curve toughening in excess of the NG structure, but less than that of the CG→NG gradient structure. However, it is less susceptible to outright fracture as the propagation of brittle cracks in the nano-grains of the early part of the gradient region become arrested once they reach the coarser-grained regions due to excessive crack-tip blunting. Therefore, the NG→CG gradient structure represents a characteristic transition from brittle fracture to ductile fracture, which might be preferred for some safety-critical applications.

This study seeks not only to develop a mechanistic understanding of the fracture behavior of GS materials, but also may provide practical guidelines for the use of such materials in safety–critical applications.

This work has been published in Materials Today collaborating with researchers from UC Berkeley.

FIGURE 1 Mechanical properties of the uniform grain-sized pure NG and pure CG structures, and gradient structured (CG→NG and NG→CG) Ni at room temperature.(a) Uniaxial tensile properties. (b) R-curves. (c) Ultimate tensile strength vs. Plastic work density. (d) Ultimate tensile strength vs. Fracture toughness. (e) Ultimate tensile strength vs. Fracture toughness at Δa= ~ 1 mm. (Image by IMR)

FIGURE 2 Crack profiles characterized on the mid-thickness cross-section under plane-strain conditions. (a) CG , (b) NG, (c) CG→NG and (d) NG→CG. (Image by IMR)