Selective hydrogenation of acetylene is an essential step in petrochemical industry. Generally, a trace amount of acetylene (0.5%-2%) in ethylene must be removed by hydrogenation to avoid poisoning of the polymerization catalyst in the following process. Palladium (Pd) based catalysts are widely accepted due to their high activity and selectivity in this reaction than other metals. In addition, the introduction of second metal components, surface modification and other solutions can further improve the ethylene selectivity of Pd. However, Pd based catalysts suffering from the drawback of high cost. Therefore, design and fabrication of non-precious metal-based catalysts with high-efficiency and low-cost is of great significance.

In the past decades, tremendous progress has been made in the design and fabrication of non-precious metal catalysts for acetylene selective hydrogenation. However, there are still obstacles impeding their utilization, such as low activity, insufficient selectivity and inconvenient preparation technics. Therefore, the design of novel high-efficiency non-precious metal catalysts for acetylene selective hydrogenation is urgent, which is highly dependent on the in-depth understanding of the structure-property relationship. Therefore, an accurate recognition of the catalyst structure is the main issue. In the past, catalyst structure was generally characterized by ex-situ techniques. Unfortunately, most of the catalyst are active to oxygen and would undergo some undesired structural changes under air condition, which block the precise establishment of the structure-property relationship. In-situ techniques are accessible for the characterization of the catalyst structure and its evolution under working conditions. The relevant studies have greatly promoted the recognition of true active structure and novel catalyst design.

Recently, based on previous studies on acetylene selective hydrogenation catalyst (Chem. Commun. 2020, 56, 6372; Angew. Chem. Int. Ed. 2019, 58, 4232; ChemCatChem 2017, 9, 3435) from this research team, Prof. ZHANG Bingsen from Institute of Metal Research, Chinese Academy of Sciences, Prof. ZHANG Wei from Jilin University, Prof. WEI Min from Beijing University of Chemical Technology, and Dr. HUANG Xing and Dr. Marc-Georg Willinger from ETH Zurich propose a new strategy to design and synthesize highly-efficiency Ni based catalysts with interstitial atoms control for acetylene hydrogenation reaction.

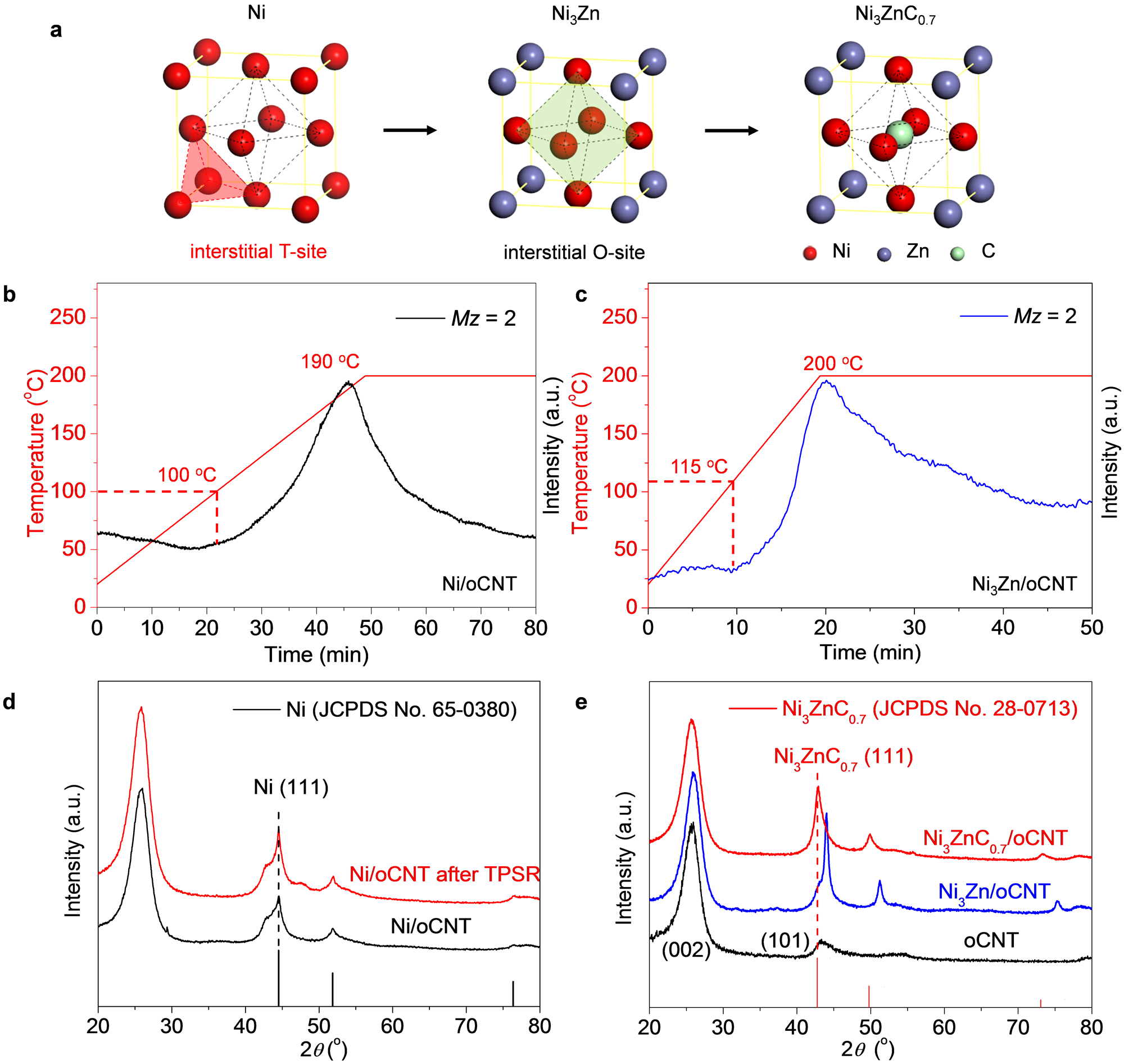

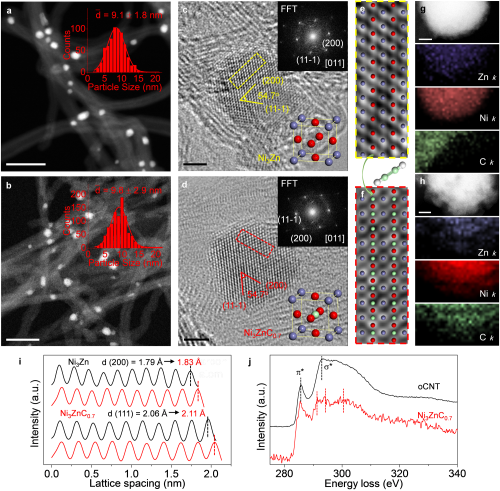

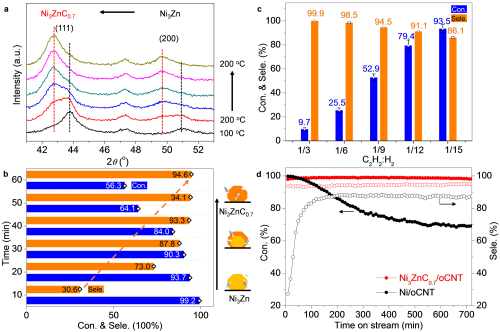

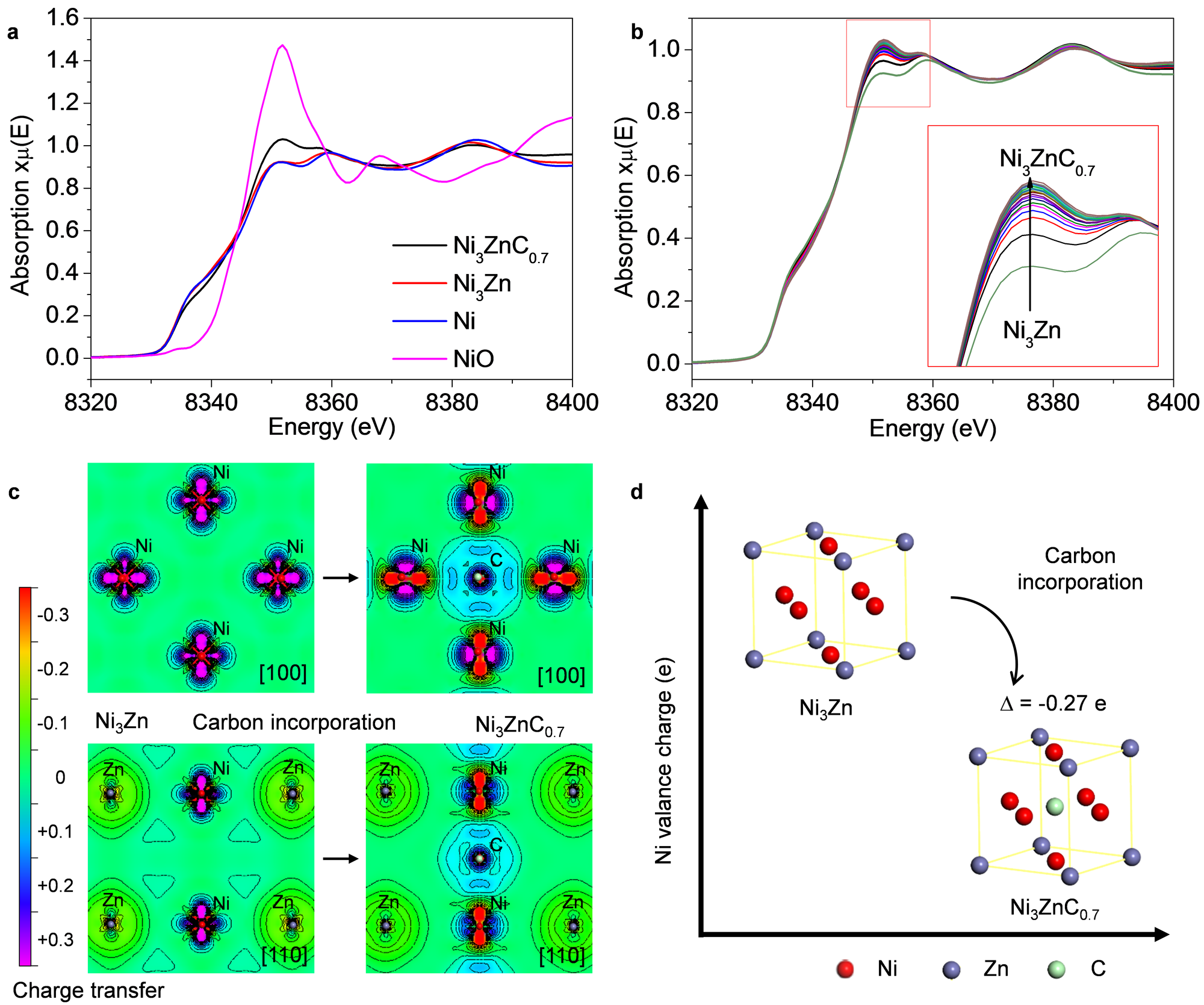

This work demonstrates that highly efficient hydrogenation of alkyne could be obtained via introducing carbon atoms within Ni lattice containing an expanded interstitial space. With an addition of 25% Zn, the interstitial space of Ni is expanded with a well-maintained capability to adsorb and dissociate hydrocarbon molecules. Thus, the dissociated carbon atoms enable readily penetrating into Ni3Zn to offer the formation of Ni3ZnC0.7 structure under acetylene contained atmosphere at 200 oC. Both XRD and TEM investigations confirm the lattice parameter expansion after the inclusion of Zn and carbon. EDX and EELS analysis explicitly reveal the existence of carbon in Ni3ZnC0.7. Combined with in-situ XANES experiments and DFT calculations, the introduced carbon atoms coordinate with the neighboring Ni atoms and impair a positive charge to Ni. As a result, the interstitial occupation in Ni3ZnC0.7 suppresses the reaction pathway of ethylene hydrogenation and increases the selectivity drastically under hydrogen-rich/poor conditions. That is to say, it can effectively bypass the temporal metastable state variation under a fluctuation reaction condition. More importantly, the formed Ni3ZnC0.7 exhibits a highly improved stability compared with Ni. As a result, the dissociation and accumulation of carbonaceous species are inhibited on the surface. Hence, our work provides a proof-of-concept to control of interstitial sites in heterogeneous metal catalyst. Moreover, such a new solution enables improving the selectivity and stability for selective acetylene hydrogenation.

These results are published on Nature Communications, Dr. NIU Yiming is the first author. This work is supported by the National Natural Science Foundation of China, LiaoNing Revitalization Talents Program and Youth Innovation Promotion Association CAS.

Figure 1. Incorporation of carbon atom in Ni3Zn(Image by IMR)

Figure 2. Microstructural characterization of Ni3Zn and Ni3ZnC0.7(Image by IMR)

Figure 3. Catalytic performance in acetylene selective hydrogenation reaction(Image by IMR)

Figure 4. Electronic structure of Ni in Ni3Zn and Ni3ZnC0.7 (Image by IMR)