Bulk metallic glass composites (BMGCs) containing in-situ formed β-Ti dendrites are promising for wide applications because of their large critical casting size, superior mechanical property and good energy-release behavior. However, it remains challenging to effectively tune their microstructures and mechanical properties for application.

Assoc. Prof. ZHANG Long and Prof. ZHANG Haifeng from Institute of Metal Research (IMR), Chinese Academy of Sciences have dedicated to the research on the formation mechanisms, microstructure controlling and mechanical behavior of BMGCs for years. They established the “two-phase quasi-equilibrium solidification theory” of this kind of BMGCs (Sci. Rep. 6 (2016) 19235), which provides the theoretical basis for tailoring microstructures of BMGCs. They also discovered the negentropic stabilization effect of the metastable β-Ti by supercooled liquid during solidification of BMGCs, and the metastable β-Ti crystals are prone to precipitating ω phase rather than transferring to α phase (Scripta Mater. 125 (2016) 19). The effects of isothermal ω-Ti precipitation on the mechanical properties of BMGCs were also clarified (Mater. Des. 133 (2017) 82). Based on the “two-phase quasi-equilibrium solidification theory”, the distribution of nearly all Be in the glassy matrix has been explained (J. Mater. Sci. Technol. 33 (2017) 708). The “two-phase quasi-equilibrium solidification theory” also provides the theoretical basis for tuning the phase (meta)stability of the β phases, and the stable β phase was tuned to be a metastable β phase in the same alloy system, which undergoes deformation-induced martensitic transformation (Mater. Sci. Eng. A 689 (2017) 404). BMGCs containing β-Ti with three typical different (meta)stabilities were also developed and studied (J. Alloy. Compd. 708 (2017) 972). During tuning the metastability of β-Ti, amorphous phase were found to exist in the as-cast Ti59.1Zr37Cu2.3Fe1.6 (at.%) polycrystalline alloys, and according to the existence morphology, distribution feature and the physical properties of the amorphous phase, the mechanism of martensitic transformation-induced solid-state amorphization and the concept of “amorphous martensite” were proposed (Nat. Commun. 9 (2018) 506). Based on the “two-phase quasi-equilibrium solidification theory”, an iteration method was invented to develop BMGCs containing β-Ti (or β-Zr) from the monolithic Ti-based or Zr-based BMGs (J. Alloy. Compd. 740 (2018) 639). It is found that the yield strength of the BMGCs is sensitive to the metastability of the β phases, and the yield strength and metastability of the β phases have been correlated by using the Eshelby method (Scripta Mater. 173 (2019) 11). The effects of particle size, phase stability and volume fraction of the β phases on the tension properties of BMGCs were systematically investigated, and then, BMGCs with a large casting-size, high yield strength, relatively large tensile plasticity, super-elasticity and good work-hardening capability have been developed (Acta Mater. 168 (2019) 24).

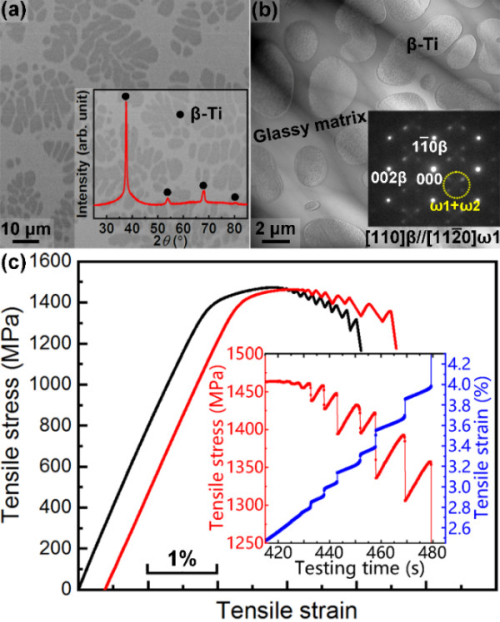

Recently, Assoc. Prof. ZHANG Long (the first author) and Prof. ZHANG Haifeng (the corresponding author) with collaborators found when the in-situ β-Ti has a marginal metastability, the BMGCs exhibit obvious serrated manners in the stress-strain curves (Fig. 1). This is very different to the previously-reported tension-behavior of BMGCs, but is similar to the compression-behavior of monolithic BMGs.

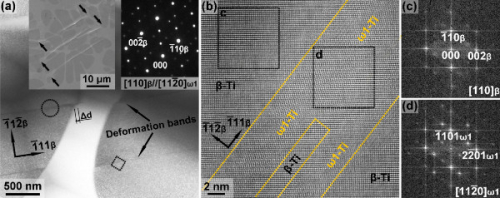

This BMGC exhibits a shear-fracture mode, and deformation bands have penetrated both the β-Ti dendrites and the local glassy matrix (Fig. 2). The deformation band with a thickness of ~10 nm in the β-Ti dendrite is mainly composed of ω-Ti, suggesting the β phase transfers to the ω phase. The serrated behavior of BMGCs under tension arises from this new plastic deformation mechanism: cooperative shear by a shear band in the glassy matrix and an ω-Ti band in the metastable β-Ti dendrite.

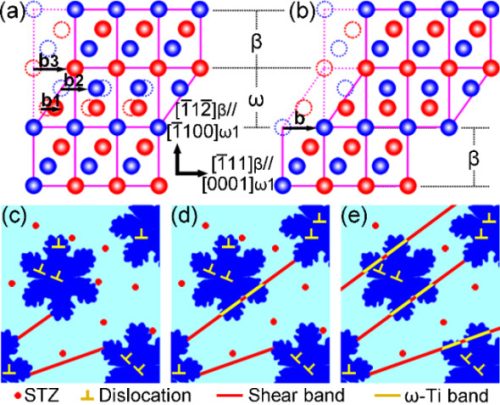

The cooperative shear by the shear band and the ω-Ti band induces the shear instability in the local region of a single dendrite (several tens of micrometers), but it is arrested by the adjacent β-Ti dendrites with different crystalline orientations. The continuous activation and arrest of the cooperative shear cause the serrations of BMGCs under tension. The formation of ω band is associated with the high strain-rates (~~103 s-1) during the cooperative shear. High strain rates activate the 1/2<111>β dislocation, which dissociates into three partials: two 1/12<111>β and one 1/3<111>β. The glid of the three partial dislocations on continuous {112} planes transfers the β phase into the ω phase (Fig. 3). This cooperative shear is strongly relevant to the metastability of the β phase.

The discovery of the cooperative shear by a shear band and an ω band not only enriches the deformation mechanisms of BMGCs, but also provides the fundamental basis for developing high energy-release BMGCs with tensile plasticity and shear-fracture mode.

These findings were published in Physical Review Letters entitled “Cooperative Shear in Bulk Metallic Glass Composites Containing Metastable β-Ti Dendrites” on July 28.

This work was supported by the National Key Research and Development Program of China, the National Natural Science Foundation of China, the Liaoning Revitalization Talents Program, Chinese Academy of Sciences, and the European Research Council under the ERC Advanced Grant INTELHYB.

Fig. 1: Microstructure and tensile stress-strain curves of the BMGC (Image by IMR)

Fig. 2: Microstructure of the tension-fractured BMGC, deformation bands have penetrated both the dendrite and the local glassy matrix (Image by IMR)

Fig. 3: Transition from β to ω and the cooperative shear by shear band and ω-Ti band (Image by IMR)