Grain boundaries are widely distributed in metallic crystals and have important impacts on their mechanical properties. Among them, high-angle grain boundaries (HAGBs) can strengthen metallic materials, but the stress concentration at HAGB often leads to fatigue damage and cracking. In view of the particularity of the interaction between twin boundaries (TBs) and dislocations, it is worth clarifying whether TB resists fatigue cracking or not.

In the past ten years, Prof. ZHANG Zhefeng's research group had carried out systematic studies on the fatigue cracking behaviors of various TBs, and some new progress has recently been published on Progress in Materials Science, 2022 (https://doi.org/10.1016/j.pmatsci.2022.101011). The main new findings are as follows:

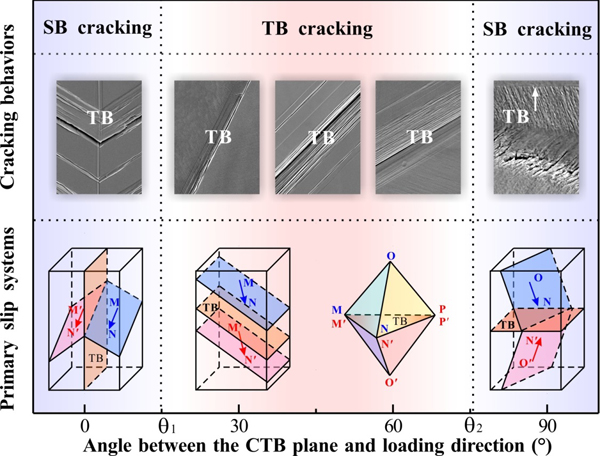

1. The included angle between the coherent TB (CTB) and the loading axis plays a decisive role in the fatigue damage. When the CTB and the loading axis have an interaction angle range of 20o - 70 o, fatigue cracks preferentially initiate along the CTB (Fig. 1 (II-IV)). In other cases, fatigue cracks preferentially initiate along the slip bands (Fig. 1 (I) and (V)).

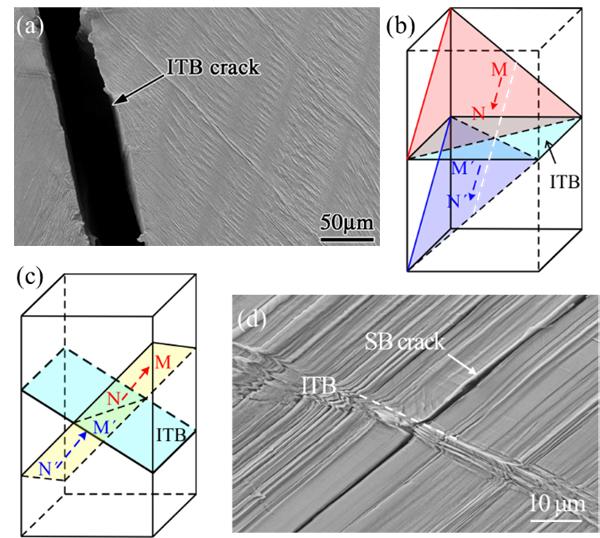

2. When the incoherent TB (ITB) is perpendicular to the loading axis (Fig. 2 (a,b)), dislocations are easy to accumulate at the ITB, leading to the preferential cracking at ITB. When the ITB is parallel or inclined to the loading axis (Fig. 2 (c, d)), the strain compatibility at the ITB is better, and fatigue cracking occurs preferentially along the slip band.

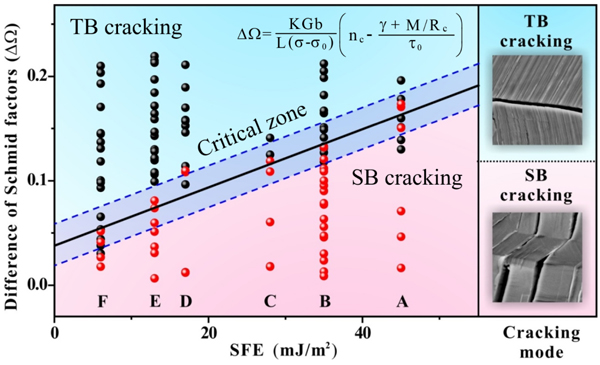

3. The fatigue cracking at TB in polycrystal is related to the stacking fault energy (SFE) and orientation. The lower the SFE is, the greater the orientation difference between the two sides of TB is, the easier is the fatigue cracking along TB; and on the contrary, the slip band is more prone to fatigue cracking. In terms of the Schmid factor difference (ΔΘ) and SFE, a quantitative criterion for fatigue cracking was established (Fig. 3).

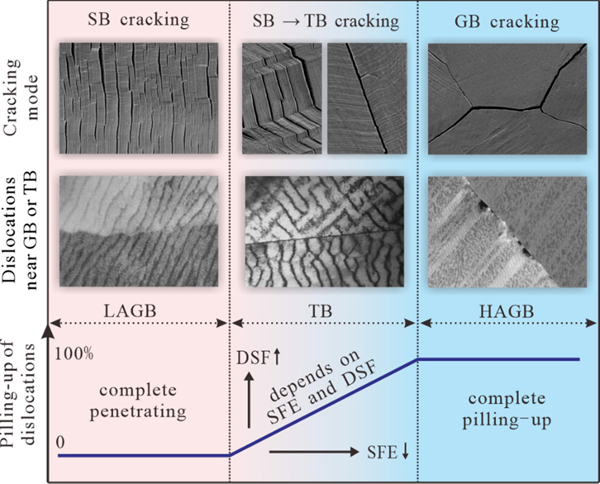

4. Combined with the previous studies on the fatigue cracking behaviors of HAGB and low-angle GB (LAGB) (Zhang ZF and Wang ZG, Prog. Mater. Sci. 53 (2008) 1025-1099), the order of the fatigue cracking resistance of different GBs decreases may be determined in an order of: HAGB > TB > LAGB, and whether the TB cracking or not depends on SFE and crystallographic orientation (Fig. 4).

The above research was supported by the projects of the Youth Innovation Promotion Association CAS (2021192) and NSFC (50571104, 50625103, 50890173, 51171194, 51471170, 51501197).

Fig. 1 Fatigue damage mechanisms corresponding to different inclination angles of CTB and loading axis of copper bicrystal (Image by IMR)

Fig. 2 fatigue damage behavior of ITB in copper bicrystal at different angles to the loading axis. (a,b) ITB is perpendicular to the loading axis; (c,d) ITB inclines to the loading axis. (Image by IMR)

Fig. 3 Synergistic effect of stacking fault energy and crystal orientation on the fatigue cracking behavior of polycrystal copper alloy (Image by IMR)

Fig. 4 Fatigue resistance of different kinds of GBs: LAGB > TB > HAGB (Image by IMR)