Al-based metallic glasses (MGs) effectively circumvent the longstanding tradeoff between corrosion resistance and mechanical properties inherent in commercial Al alloys due to their distinctive structural and compositional attributes. And they are ideal model system for revealing the relationship between alloy elements and alloy corrosion from multiple scales.

In the past ten years, Prof. WANG Jianqiang's research group from Institute of Metal Research, Chinese Academy of Sciences (IMR, CAS) had carried out systematic studies on the corrosion behaviors of Al-based MGs. Based on relevant work, they proposed a review of the underlying mechanism for the effects of composition and microstructure on the corrosion resistance of Al-based MGs. This work was published in the Critical Reviews in Solid State and Materials Sciences.

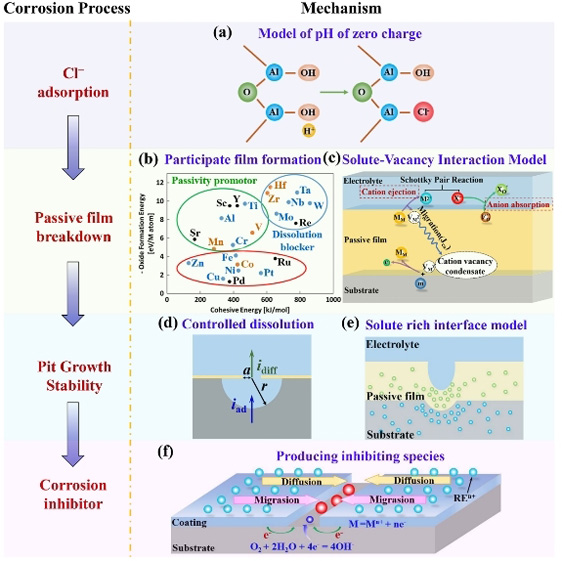

From the perspective of composition, the mechanisms of alloying elements on corrosion resistance of Al-based MGs was analyzed based on the different stages of pitting corrosion (Fig.1). For example: Inhibiting the adsorption of aggressive ions by controlling the pH of zero charge; Reducing the point defect density in a passive film with the solute-vacancy interaction model; Inhibiting pitting growth by solute rich interface model and on-demand release of corrosion-inhibiting ions in the corrosion process. In addition, the effects of structural evolution (such as atomic clusters, structural relaxation, nanocrystallization, etc.) on the corrosion resistance mechanism of Al-based MGs are described from different structural scales (Fig. 2). Based on insights drawn from this exhaustive review of the literature, it advocates for further investigations aimed at advancing the development of corrosion-resistant Al-based MGs.

The work was supported by National Natural Science Foundation of China and the Key Research Program of the Chinese Academy.