A breakthrough in manufacturing could revolutionize a critical component found in everything from power electronic devices- to pulsed lasers: dielectric energy storage capacitor. These capacitors are prized for their demonstrating remarkable durability to ultra-rapid charge and discharge at very high-power levels. Yet, scientists have long grappled with a fundamental challenge: how to develop capacitors that not only deliver high energy storage capacity but also endure extreme temperatures- from deep freeze to intense heat-and remain suitable for mass production?

Traditional fabrication methods rely on intricate techniques such as chemical doping, multi-phase composition, or the deliberate introduction of structural defects to engineer materials with specific microstructures,which are often complex and time-consuming, hindering the scalable production of high-performance dielectric films.

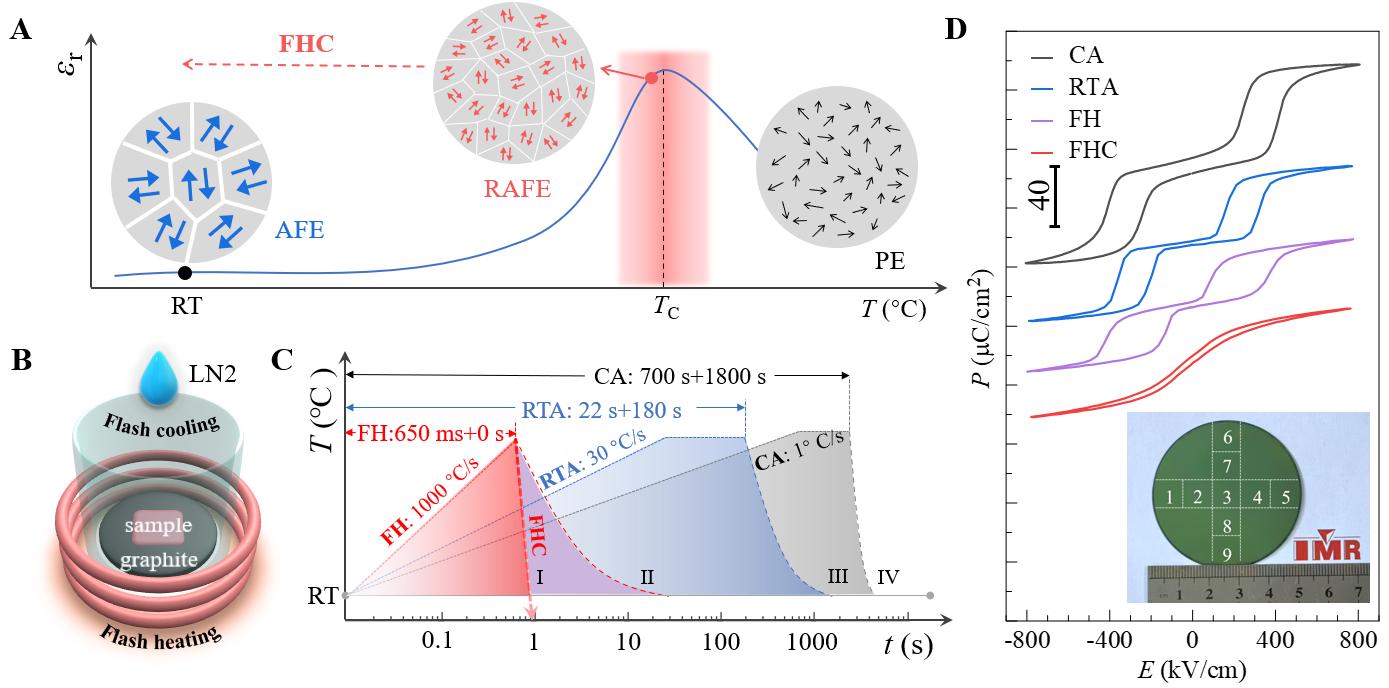

Recently, a research team led by Prof. HU Weijin at the Institute of Metal Research, Chinese Academy of Sciences (IMR, CAS) has developed a breakthrough "flash annealing" technique. This process achieves astonishing heating and cooling rates of up to 1000°C per second. Using this method, the team successfully synthesized a relaxor antiferroelectric lead zirconate film on a silicon wafer in just one second.

So, what is the secret behind this one-second 'ice-fire' forge?

The technique effectively "freezes" the material's high-temperature paraelectric phase structure at room temperature. This creates nanoscale maze of domains smaller than 3 nanometers,, which is the key to triggering high-performance relaxor antiferroelectric behavior and enabling highly efficient energy storage. Simultaneously, the flash annealing process results in a denser, more uniform film texture and effectively suppresses the evaporation of volatile lead elements. Together, these enhancements allow the film to withstand extremely high electric fields while achieving strong polarization, ultimately boosting the energy storage density of the capacitor to 63.5 J/cm³.

The capacitors produced with his method also demonstrate the outstanding thermal stability. After thermal cycling from the extreme cold of -196°C (liquid nitrogen temperature) to scorching temperatures up to 400°C, the degradation in energy storage density and efficiency remains minimal-below 3%. This reliability makes them suitable for the harshest environment, from the icy void of outer space to the high-temperature environment of an underground oil exploration well.

Moreover, the technology is simple and scalable. The team has already produced uniform, high-performance films on 2-inch silicon wafers, offering an industrially viable pathway toward chip-integrated energy storage solutions.

This work, entitled “Flash annealing-engineered wafer-scale relaxor antiferroelectrics for enhanced energy storage performance”, was published in the journal “Science Advances” on November 15 (Beijing time), marking a new avenue for manufacturing next generation high-performance energy storage capacitors.

Rational Design Principles of Relaxor Antiferroelectric Materials. (a) Temperature-dependent dielectric permittivity (εr) of an antiferroelectric (AFE) material, with schematic domain structures illustrate at different temperatures. (b) The experimental setup for flash heating and flash cooling (FHC), capable of achieving rates up to 1000 oC/s, enabling the synthesis of relaxor AFE films in just one second. (c) Comparison of various heat treatment protocols, with treatment times ranging from under 1 second for FHC to over 1000 seconds for conventional annealing (CA). (d) P–E hysteresis loops of PbZrO3 films subjected to various annealing processes. The inset shows a 2-inch wafer-scale relaxor AFE film fabricated via FHC. (Image by IMR)