Researchers from the Institute of Metal Research, Chinese Academy of Sciences (IMR, CAS) have set a new world record in exploring the theoretical limit of metal fatigue strength. This work, published in National Science Review, not only achieves unprecedented performance but also establishes fundamental principles for fatigue-resistant material design.

Fatigue strength is a critical indicator affecting the reliability and lifespan of materials and components. Enhancing it improves long-term durability, supports lightweight designs, boosts energy utilization efficiency.

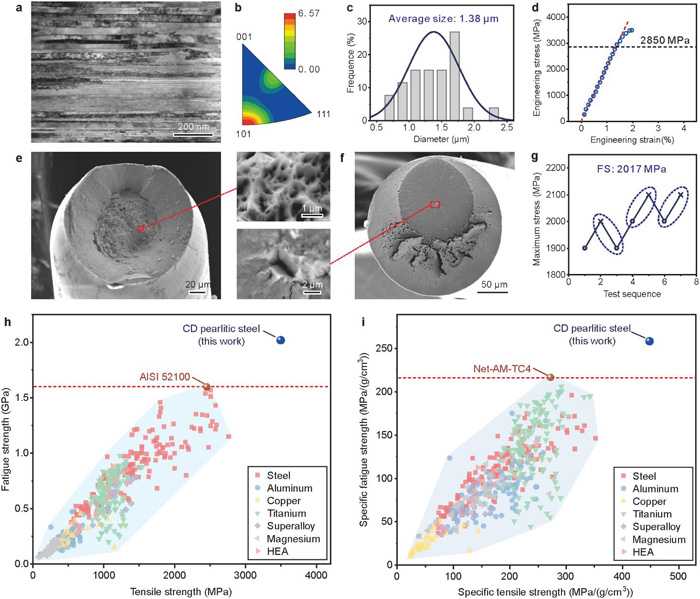

Led by Prof. ZHANG Zhefeng, the research team addressed the fundamental question "How high can the fatigue strength of metals be achieved?". In response, they proposed four key principles for fatigue-resistant design: high elastic modulus to define the theoretical strength limits, "fine-stable-uniform" microstructure to eliminate significant weak regions, minimal inclusion or defect size to reduce stress concentration, and optimized tensile properties that combine high elastic limit with strain hardening capability.

By applying these principles to cold-drawn pearlitic steel wires, the team achieved an extraordinary tensile-tensile fatigue strength of 2017 MPa, surpassing the previous world record of 1600 MPa by 26%. This breakthrough was realized through several innovations : developing strong a <110> texture via cold drawing to eliminate weakly oriented lamellae, achieving an ultra-high elastic limit (2850 MPa) and tensile strength (3525 MPa) using synergistic strengthening mechanisms, and reducing the average inclusion size to just 1.38 μm through ultra-purification and multi-pass drawing.

This research not only sets new benchmarks for fatigue performance but also offers valuable insights for developing next-generation high-reliability engineering materials. Potential applications span aerospace, transportation, and energy sectors.

The Four Principles of Fatigue-Resistant Design for Metallic Materials and the World Record Fatigue Strength Achieved in Cold-Drawn Pearlitic Steel Wires. (Image by IMR)