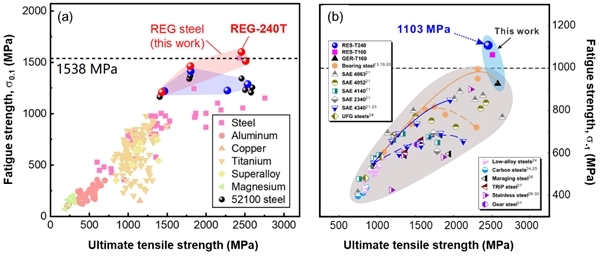

Improving the fatigue strength of metallic materials is crucial for ensuring the safe service of engineering components. As the metallic structural material currently known to possess the highest fatigue strength, high-strength steel has long achieved tensile strengths exceeding 3 GPa. However, its tension-compression fatigue strength has remained stagnant, unable to break the 1 GPa bottleneck. Recently, a collaborative effort between the research team led by Prof. ZHANG Zhefeng and the team led by Academician LI Dianzhong has achieved a new breakthrough in the fatigue cracking model and performance optimization of GCr15 bearing steel. By establishing a synergistic control theory for inclusions and strength-toughness and employing rare earth modification technology, they successfully increased the tension-tension fatigue strength of the bearing steel to 1600 MPa and the tension-compression fatigue strength to 1103 MPa. These figures represent improvements of 4% and 10%, respectively, over the existing world records for tension-tension and tension-compression fatigue strength.

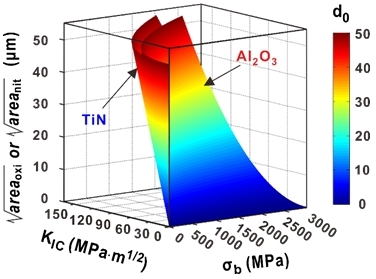

First, the research team systematically analyzed the fatigue cracking behavior and fatigue life of two types of inclusions, TiN and Al₂O₃, in GCr15 bearing steel. They revealed that the fundamental reason for the differing impacts of these inclusion types on fatigue life lies in their significantly different stress concentration effects. Quantitative simulation analysis showed that under identical size conditions, the fatigue life damage coefficient of Al₂O₃ inclusions is approximately 30% higher than that of TiN. This provides a theoretical basis for precise control of nitrogen and oxygen elements during the smelting process of high-strength steel.

Secondly, to address the challenge of decreasing fatigue strength at high strength levels due to inclusion cracking, the research team innovatively proposed the "critical inclusion size criterion for fatigue cracking." They established a quantitative relationship among tensile strength, fracture toughness, and inclusion size during fatigue cracking of high-strength steel. This successfully achieved the goal of synergistic optimization of strength and toughness to resist fatigue under given inclusion parameters, providing a new theoretical criterion for the design and manufacturing of high-strength steel with optimized fatigue strength.

Subsequently, they modified the GCr15 bearing steel by adding rare earth elements. This modification significantly reduced inclusion size, enhanced the deformability of inclusions under fatigue loading, and formed an inclusion-matrix interface capable of shear deformation, thereby reducing the degree of stress concentration caused by inclusions. Building upon this inclusion control and combined with the fatigue strength optimization criterion, they adjusted the heat treatment to its optimal state. This resulted in a fatigue-resistant high-strength steel with a tension-tension fatigue strength of 1600 MPa and a tension-compression fatigue strength of 1103 MPa. These values represent improvements of 4% and 10%, respectively, over the existing world records for tension-tension fatigue strength (1538 MPa) and tension-compression fatigue strength (1000 MPa).

The research findings on the breakthroughs in tension-compression and tension-tension fatigue strength were recently published in Acta Materialia and Journal of Materials Science & Technology, respectively.

This research achievement not only breaks the world records for high-strength steel fatigue strength but, more importantly, establishes a systematic anti-fatigue theoretical framework of "inclusion control-strength-toughness matching-defect interface optimization." It provides a novel technological pathway for the development of high-end bearing materials in critical fields such as aerospace and rail transportation.

Fatigue cracking criterion for inclusions (Image by IMR)

Breakthrough in fatigue strength of high-strength steel: (a) Tension-tension fatigue strength; (b) Tension-compression fatigue strength. (Image by IMR)