Researchers from the Institute of Metal Research, Chinese Academy of Sciences (IMR, CAS) have developed a 3D-printed titanium alloy that demonstrates record-breaking fatigue performance across all stress ratios, overcoming a major obstacle in the engineering application of additive manufacturing.

The study, published in Science Advances, addresses the longstanding challenge of poor fatigue performance in 3D printed materials—a key limitation for their use in aerospace and other safety-critical industries where components often experience complex, variable stress patterns during service.

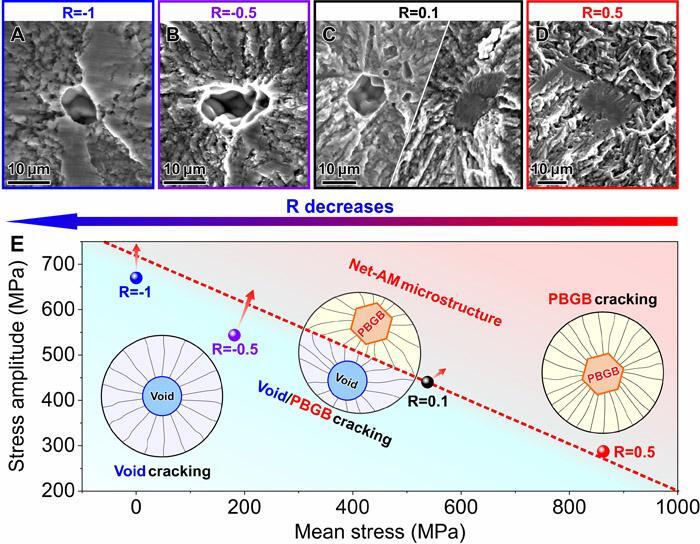

Building upon earlier research published in Nature (2024), where the team established a new world record for tensile-tensile fatigue strength in Ti-6Al-4V alloy, this latest work systematically investigated fatigue behavior under varying stress ratios. The researchers discovered that conventional titanium alloy microstructures typically exhibit fatigue resistance only within specific stress ratio ranges due to different cracking mechanisms becoming dominant under different loading conditions.

Using the team's original Net-AM (Net-Additive Manufacturing) process, which produces nearly pore-free microstructures, the newly developed material demonstrates exceptional fatigue strength across all stress ratios. Comparative analysis confirms that the Net-AM Ti-6Al-4V alloy outperforms all existing titanium alloys in fatigue strength while its specific fatigue strength (fatigue strength divided by density) surpasses that of all metallic materials.

This work reveals that 3D printed titanium alloys possess inherently high fatigue resistance across all stress ratios, breaking the traditional performance limitations of additively manufactured materials. The findings validate additive manufacturing as a viable technology for producing load-bearing components in aerospace applications.

The research also provides new insights for optimizing fatigue performance in forged titanium alloys under different stress conditions, offering broader implications for materials design in high-performance engineering applications.

Typical fatigue fracture surfaces and corresponding fatigue crack initiation mechanisms of net-am structured ti-6al-4v alloy under different stress ratios (Image by IMR)