Researchers from the Institute of Metal Research, Chinese Academy of Sciences (IMR, CAS) have made significant progress in understanding and quantifying hydrogen-induced damage in titanium alloys under deep-sea conditions, establishing a safety service criterion for critical marine equipment, with findings published in Acta Materialia.

Titanium alloys are widely used in deep-sea applications due to their excellent mechanical properties and corrosion resistance, attributed to their self-repairing passive oxide films. However, they remain vulnerable to hydrogen-induced damage, particularly in deep-sea environments where low oxygen concentrations promote cathodic polarization.

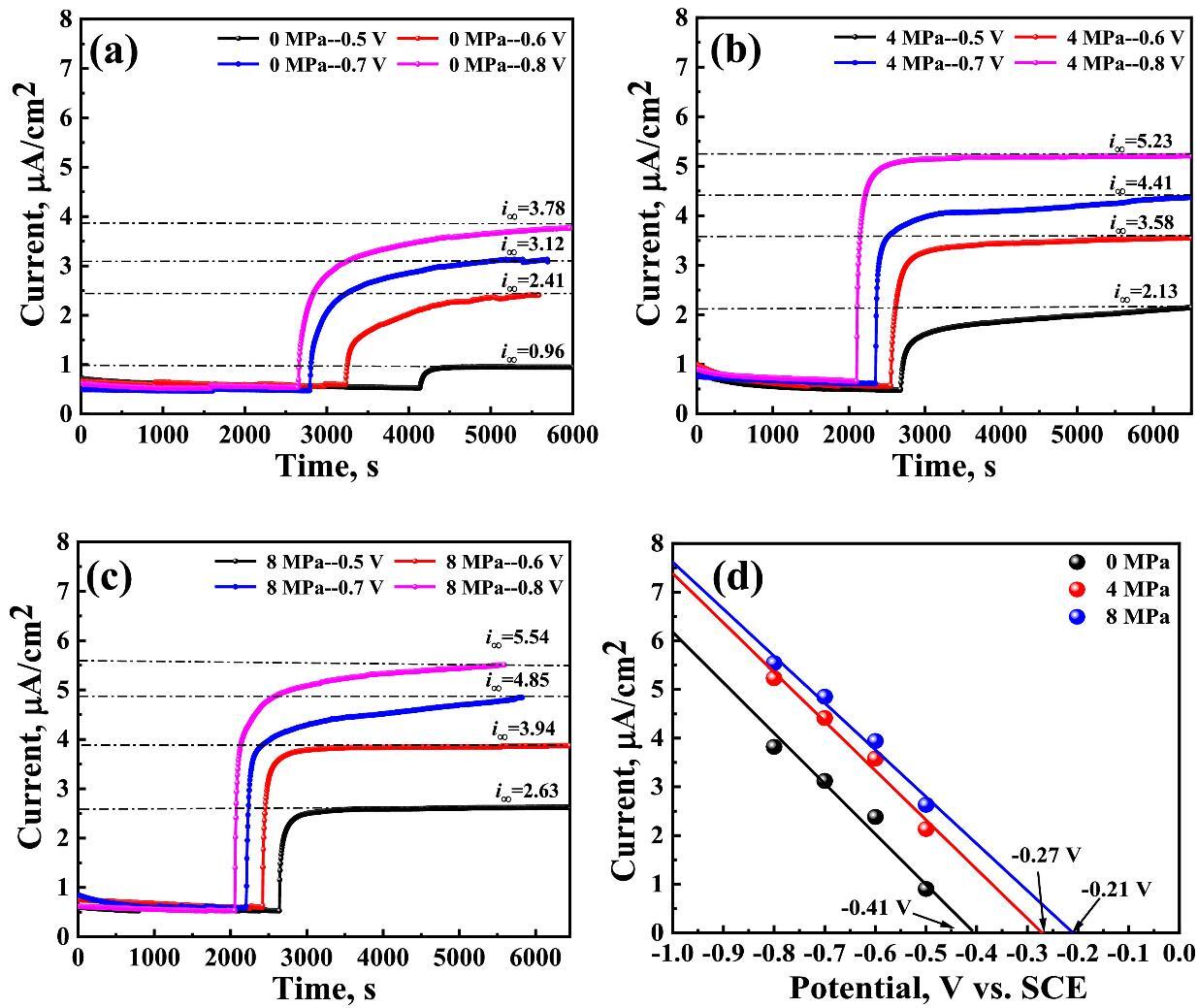

The research team led by Prof. SONG Yingwei discovered a previously unknown phenomenon: "hydrostatic pressure-induced positive shift of hydrogen damage threshold potential." Using in-situ hydrogen permeation testing under simulated deep-sea pressure, they quantified how the threshold potential shifts from -0.41 V (SCE) at atmospheric pressure to -0.21 V (SCE) under 8 MPa pressure—equivalent to approximately 800 meters depth.

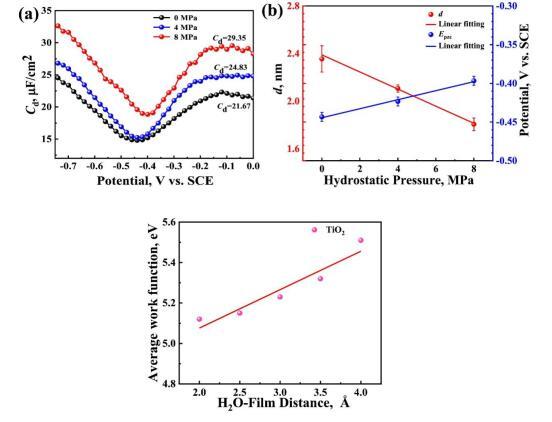

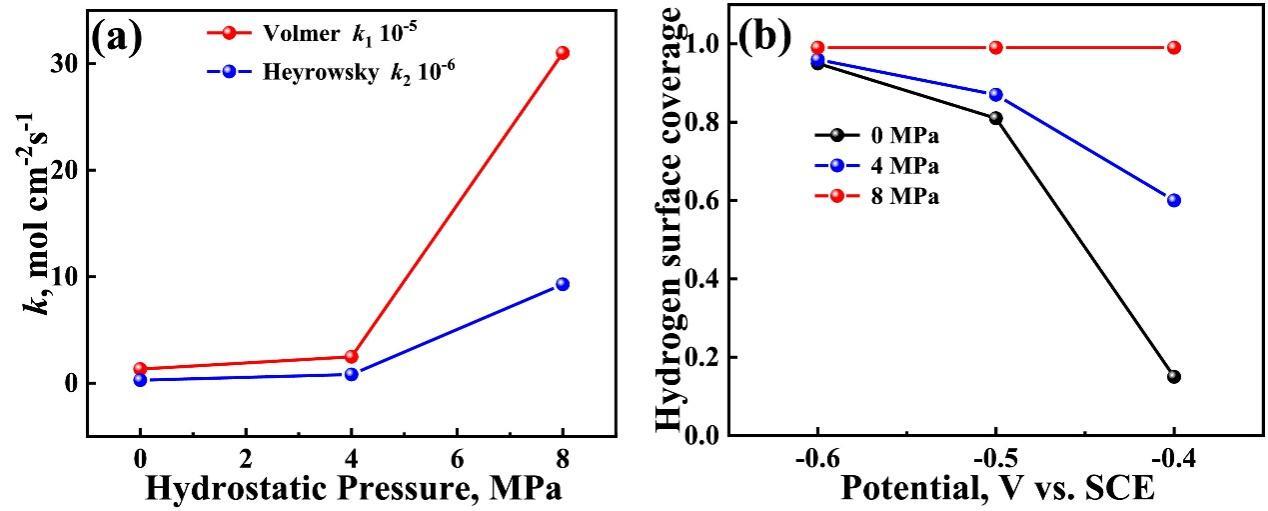

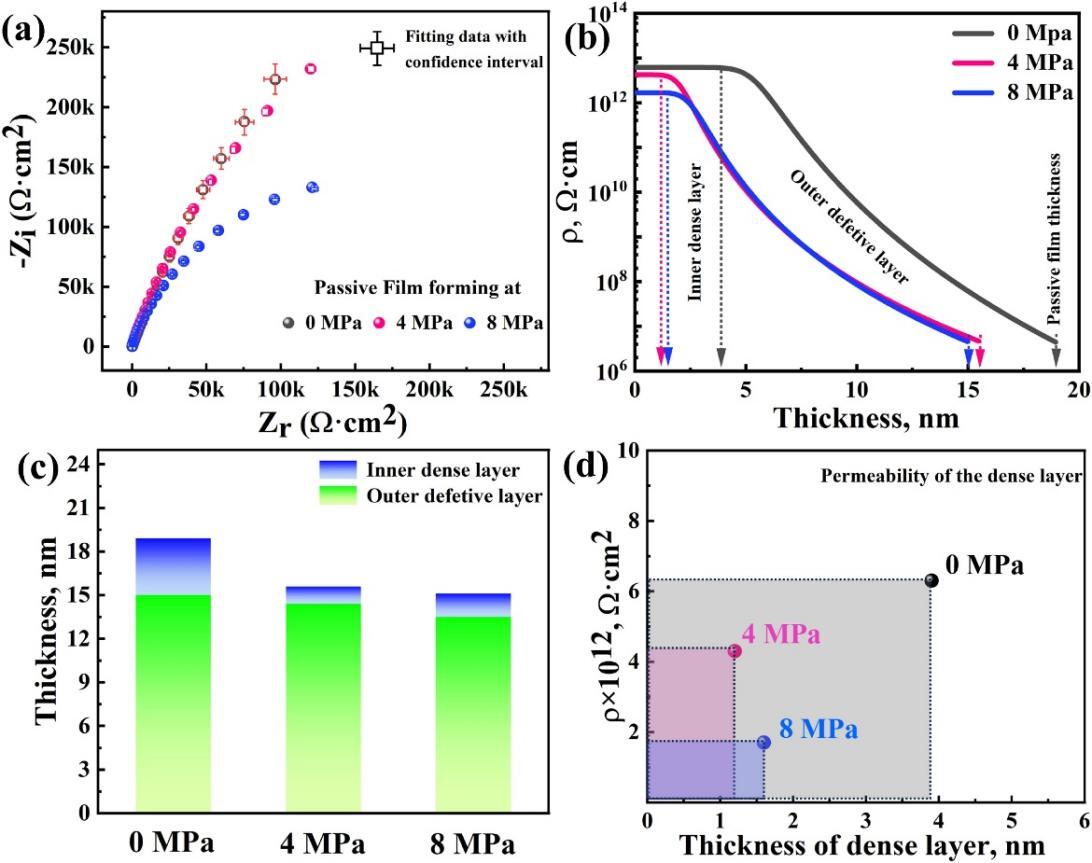

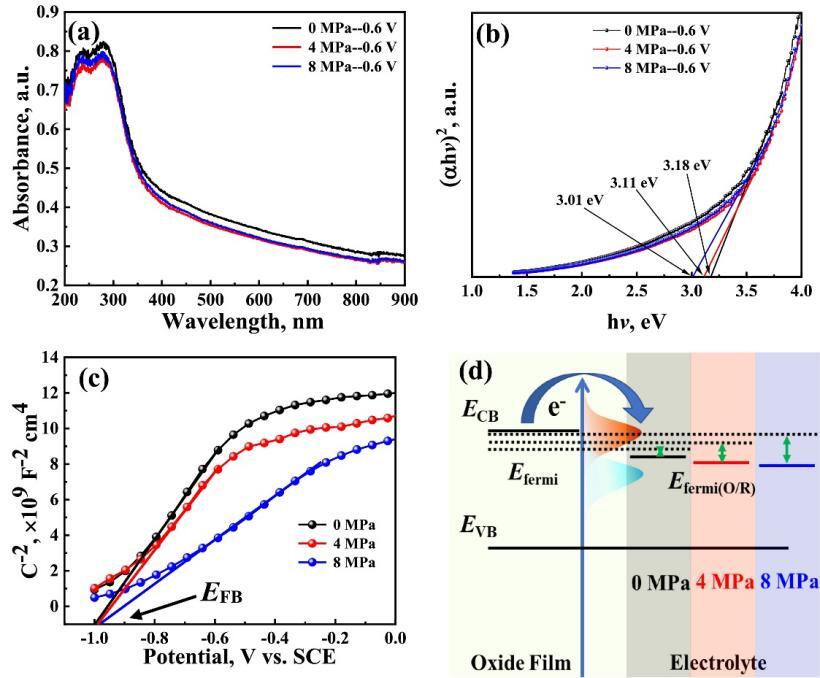

The study reveals hydrostatic pressure's dual role in accelerating hydrogen damage. First, it compresses the Helmholtz layer thickness at the electrode surface by about 23%, increasing interfacial electric field strength and exponentially accelerating hydrogen evolution reaction kinetics. Second, it degrades the passive film, reducing its dense inner layer thickness by over 50% (from 3.9 nm to 1.6 nm) while increasing defect density, severely compromising its barrier function against hydrogen penetration.

"This work establishes a comprehensive model linking interfacial electric fields, hydrogen evolution kinetics, and passive film properties under high pressure," explained by the research team. "The findings provide crucial theoretical guidance for designing hydrogen-resistant titanium alloys for deep-sea applications."

The research establishes a safety service criterion based on threshold potential for hydrogen damage, addressing a critical theoretical gap in deep-sea engineering design and offering important support for the long-term safe operation of submersibles, deep-sea stations, and other marine equipment.

Hydrogen permeation and threshold potential under deep-sea hydrostatic pressure environment (Image by IMR)

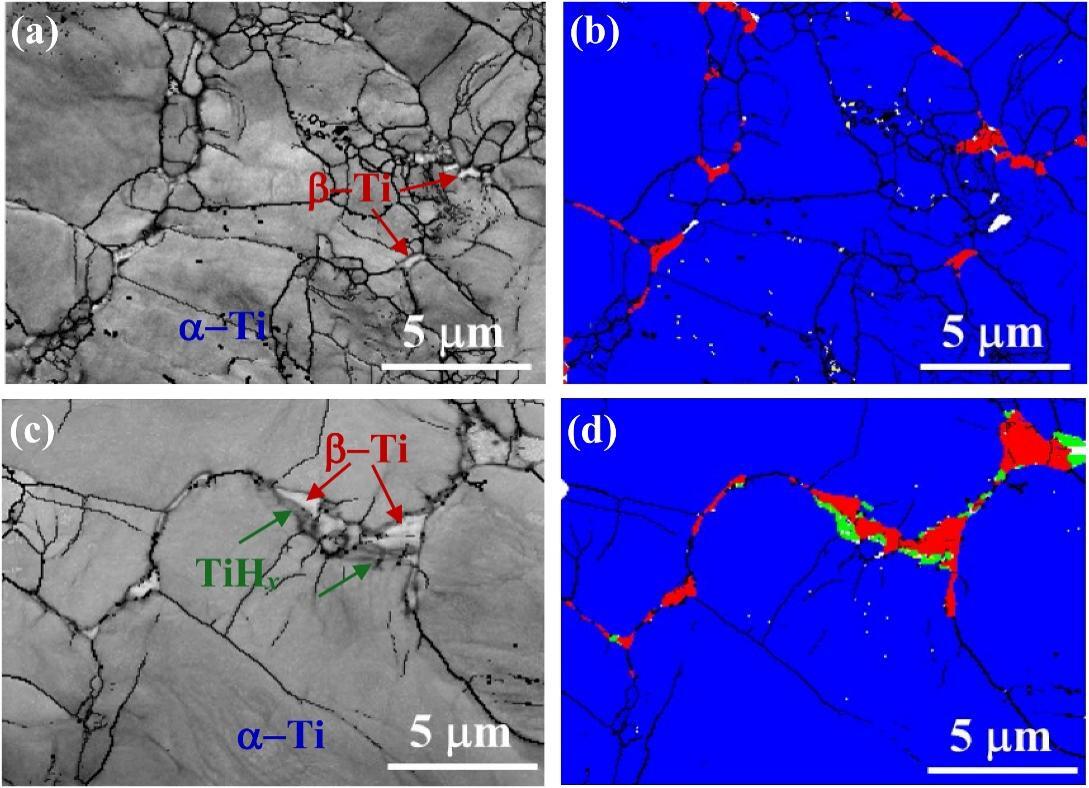

Verification of threshold potential for hydrogen-induced damage of titanium alloys (Image by IMR)

Hydrostatic pressure alters the structure of interfacial electric double layer and increases interfacial electric field strength (Image by IMR)

Hydrostatic pressure significantly enhances Volmer hydrogen evolution reaction and hydrogen surface coverage (Image by IMR)

Hydrostatic pressure reduces the thickness and compactness of passive film (Image by IMR)

Hydrostatic pressure changes the band structure of semiconductor passive film and promotes electron transfer. (Image by IMR)