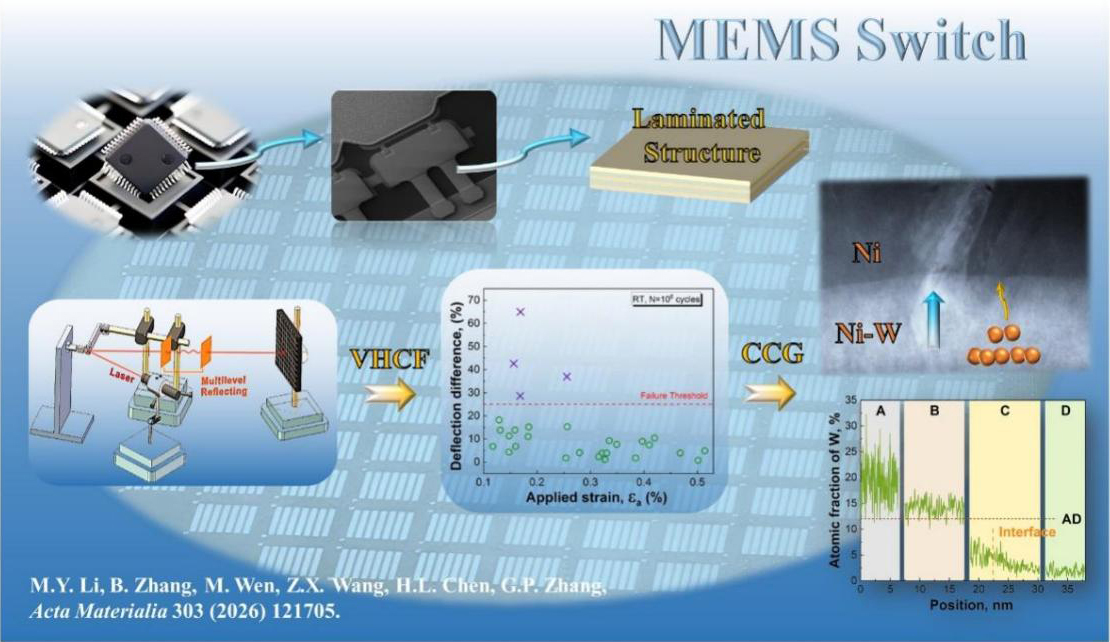

Researchers from the Institute of Metal Research, Chinese Academy of Sciences (IMR, CAS) have made progress in developing high-performance materials for micro-electromechanical system (MEMS) switch chips, achieving ultra-long fatigue life critical for 5G/6G communication, aerospace, industrial control and medical applications.

MEMS switches, which contain micro-cantilevers capable of undergoing 10 billion bending cycles, require materials combining excellent conductivity, high strength, and exceptional fatigue resistance. While gold and its alloys have been widely used due to their low resistivity and microfabrication compatibility, their limited strength and fatigue performance fall short of demanding longevity requirements.

The research team led by Prof. ZHANG Guang-Ping has successfully developed nanocrystalline Ni/Ni-W laminated composites demonstrating remarkable fatigue durability. Using their self-developed ultra-high-cycle fatigue testing system for micro-materials, the team discovered that the fatigue performance of the novel material surpasses current required lifetime threshold by approximately 60% when subjected to one billion bending cycles.

The breakthrough stems from unique self-regulating mechanisms activated during fatigue loading. Nanograin rotation in the Ni-W alloy layer initiates atomic diffusion pathways, driving Ni atoms from smooth Ni/NiW interfaces toward rough interfaces. This creates a chemical composition gradient, with W-depleted regions near rough interfaces enhancing deformation compatibility and stress concentration resistance, while W-rich regions near smooth interfaces promote the continuous formation of high-density nanotwins and stacking faults, significantly reducing cyclic plastic strain accumulation.

"The synergistic effects of 'nanotwin-assisted limited grain coarsening' and 'diffusion-mediated chemical composition gradient' effectively suppress cyclic strain localization and delay fatigue damage evolution," explained the research team.

Currently collaborating with domestic semiconductor leaders, the team has achieved a "zero-to-one" breakthrough by successfully integrating their high-performance micro-cantilever material preparation with standard MEMS processes, paving the way for next-generation solid-state switch and RF relay chips.